History of Intermetall Semiconductors

History of Intermetall Semiconductors

Copyright 2015 Mark P D Burgess and Wolfgang Gebert

The authors gratefully acknowledge the seminal work by Kai Handel in his PhD dissertation Anfänge der Halbleiterforschung und –entwicklung [Handel 1999] which covers the technical history of four German semiconductor pioneers and forms the foundation for this article. This reference is not noted further throughout our article.

Prologue

Intermetall was formed in 1952 and Herbert Mataré was its founder scientist thereby beginning another important chapter in his remarkable life.

Throughout World War II Mataré had worked at the Research Laboratories of Telefunken on improved high frequency crystal detectors and duo diodes for cm radar. In the wake of the Allied occupation at the end of the War he was interrogated and ultimately offered a position in France working under French Government contracts for CFS Westinghouse. There he joined Heinrich Welker who had worked through the War at the University of Munich on the production of high purity germanium for use in point contact detectors and the theory behind them. His work was commercialised by Siemens.

Throughout World War II Mataré had worked at the Research Laboratories of Telefunken on improved high frequency crystal detectors and duo diodes for cm radar. In the wake of the Allied occupation at the end of the War he was interrogated and ultimately offered a position in France working under French Government contracts for CFS Westinghouse. There he joined Heinrich Welker who had worked through the War at the University of Munich on the production of high purity germanium for use in point contact detectors and the theory behind them. His work was commercialised by Siemens.

Left: Herbert Mataré from Mataré archives

Between them they had the knowledge and experience needed to establish a semiconductor development laboratory that would support the production of new crystal detectors for the French. Welker knew how to make high purity germanium and Mataré had experience in diode production.

Westinghouse set up a laboratory for Mataré and Welker at Aulnay-sous-Bois near Paris. This was successful and by early 1948 Westinghouse had built a production line with a capacity of 10-20,000 germanium detectors per month. [Botelho 1994]

In the second half of 1948 Mataré produced an amplifying crystal device named the Transistron. Mataré says the genesis of the concept went back to his wartime work on duo-diodes: these had two point contacts on germanium and therefore had the same geometry as a point-contact transistor although the purpose of the duo diode was noise cancellation. [Mataré H 1998] The French never suggested that they were first to invent the transistor: credit goes to Bell Laboratories. However, Mataré did assert their work discovered transistor action independently and the timing of their finding (only weeks after the announcement of the Bell’s discovery) does support this claim.

A year later there was a formal launch of the Transistron by the State Minister for Telecommunications. Several applications for the device were illustrated and the media hailed the discovery as a triumph. Despite the drama of this occasion, government support for Westinghouse was reduced. The quality of Westinghouse diodes was criticised and the State owned laboratory, SRCT, took back transistor developments. As distinguished theoretical physicists, Mataré and Welker did not intend being trapped in a company mass producing diodes. This was the dawn of the semiconductor age and both men still had a major contribution to make.

Formation of Intermetall

Jakob Michael had made his fortune in Germany in the early 1920s through investments in metals and chemicals. By the mid 1920s he was one of the most successful entrepreneurs in Germany with investments in transport, banking and insurance. In 1930 he founded the department store chain, DeFaKa (Deutsches Familien-Kaufhaus GmbH or German Family Stores). In the early 1930s he moved to the Netherlands before immigrating to the United States in 1939 in order to escape the looming perils of a Nazi Europe. During the war he was able to retain control of his holdings as it was not apparent to the Nazi authorities that they were foreign owned. [Jaeger 1994]

Jakob Michael had made his fortune in Germany in the early 1920s through investments in metals and chemicals. By the mid 1920s he was one of the most successful entrepreneurs in Germany with investments in transport, banking and insurance. In 1930 he founded the department store chain, DeFaKa (Deutsches Familien-Kaufhaus GmbH or German Family Stores). In the early 1930s he moved to the Netherlands before immigrating to the United States in 1939 in order to escape the looming perils of a Nazi Europe. During the war he was able to retain control of his holdings as it was not apparent to the Nazi authorities that they were foreign owned. [Jaeger 1994]

Following the end of the War the Allies imposed reparations, currency controls and attempted a programme to curtail the industrial strength of Germany (particularly heavy industries). Continuing its pre-war policies, the domestic economy remained tightly regulated but then liberalised in the period 1945-1948 resulting in rapid economic growth. By 1950 the DeFaKa chain was trading well but Michael had a problem: the new Deutschmark was not a tradable currency and Michael could not transfer the profits of the business from Germany to the United States.

In 1951 Reschowsky, a lawyer acting for Michael, met with Mataré to discuss a proposal: Michael would fund the establishment of a semiconductor company to produce diodes and transistors from the profits of his German businesses. The company would export its products to the USA through Michael’s USA company effectively transferring German profits to the USA. This was a rational plan driven by a tempting opportunity: despite the promise of the transistor when announced to the world in 1948 and the adoption of transistor research and development by many companies, transistors were virtually unobtainable in the USA. Of the estimated 8,500 point-contact transistors being manufactured monthly, most were for the military. [Radio Electronics July 1952]

Mataré accepted the offer, resigning from CFS Westinghouse early in 1952.

Thus the company, formally called “Intermetall - Gesellschaft für Metallurgie” was set up in 1952. Its initial capital was DM 20,000 of which DM19,000 was subscribed through DeFaKa and DM1,000 was subscribed by an import-export subsidiary of DeFaKa, Bollenhagen & Co.

The name “Intermetall” was an invented name, suggesting the idea of semiconductors in general (near metal) and because Mataré intended to develop “intermetallic” compounds (ie III-V compound semiconductors). [Riordan 2004] To set up the new company Mataré needed skilled engineers and technicians, premises and specialist equipment. Key staff were recruited from CFS Westinghouse:

Robert Stasek: An engineer who would provide engineering and scientific support

Oskar Walter: Purification of germanium

Georges Calon: Mass production of diodes and applications

A little later the chemist Oskar Roesner was recruited from Otavi-Minen, a company that had supplied germanium to CFS Westinghouse.

By hiring a team with several years’ expertise each, Intermetall would fast track its development of new products.

Mataré favoured moving to Dusseldorf because he had an uncle in that city. Premises for the new plant and laboratory were found at 19-29 Zimmerstrasse, Friedrichstadt. The company was launched with 14 employees: some responsible for setting up a production facility for germanium diodes and transistors and others to staff the development laboratory which would explore III-V compound semiconductors. Early on the emphasis was on a materials research team while preparations were made for the mass production of diodes and transistors. The laboratory had some ten scientists of which about half were PhD scientists from Telefunken.

Production and testing equipment had to be purchased or made by Intermetall. This included chlorination, distillation and hydrogenation plant for the chemical production of pure germanium powder, Czochralski crystal pulling equipment for producing single crystal germanium rods and zone refining equipment for producing germanium of ultra high purity. Leybold, a specialist equipment and vacuum company, supplied their first vacuum silicon pulling apparatus.

Delivery of Equipment to Intermetall. Picture licensed by AIP Emilio Segre Visual Archives, Gift of Herbert Mataré

Jigs were made to make the hand assembly of semiconductor devices more efficient and instrumentation was produced to enable diodes (or transistors) to be tested during assembly and prior to the point contacts being fixed in place. Some of this equipment is illustrated below:

Left: Zone melting germanium at Intermetall 1953. The vacuum pump (right) is used to evacuate the quartz tube. A graphite boat holds the germanium. The heating coil (left front) can be moved along the tube, and the germanium is melted zonally Right: Oskar Walter designed Intermetall’s Czochralski apparatus (right). A germanium single crystal is shown (left). [Source Handel 1999 Mataré archives.]

Left: RF annealing furnace for germanium recovery. Right: Thermoelectrically controlled zone melting furnace for producing germanium for transistors. [Möller 1953]

This enabled Intermetall to make high quality doped semiconductors using best international practise. Once produced an automated process cut each crystal into wafers using a diamond saw. These were etched to eliminate surface defects. The point contacts were made from electrolytically pointed 0.1mm wire. In production these were fused to the germanium using an electric pulse.

By March 1953 the factory was production ready and some 25 to 30 new employees were hired for development, production and quality control. By mid 1953 20,000 germanium diodes per month were being produced.

First Commercial Diodes

The first mass produced germanium point contact diodes were produced in 1953 and price lists gave eight different diodes of the M-series, which worked satisfactorily at an operating temperature of -20 °C to +60 °C and peak voltages from 25 to 160 volts costing between DM 3.20 and DM 6.00.

Diode test facility at Intermetall, Dusseldorf 1953 [Funkschau 1953 18]. Intermetall used 14 characteristics plotters developed in-house and female labour to carryout final measurements of diode performance.

The range was intended for use in applications requiring light weight, high

The range was intended for use in applications requiring light weight, high mechanical and electrical stability and high efficiency rectifiers such as in radio, television and communication equipment and computing devices.

mechanical and electrical stability and high efficiency rectifiers such as in radio, television and communication equipment and computing devices.

The type number provided the key characteristics. For example in the case of the M 550 the first “5” represented the forward current at 1 volt and the “50” is the reverse voltage for a leakage current of 800 μA (except for the M550a and M 550b).

Left: Intermetall germaniumdiodes in 1953 Source Handel 1999 Mataré archives. Right: Intermetall M550b Diode from Richter 1956

|

Characteristics of Intermetall First Diodes 1953 |

|||||||

|

Type Number |

Min Forward current at 1V mA |

Max Leakage Current, μA |

At Reverse Voltage, V |

Max Leakage Current, μA |

At Reverse Voltage, V |

Max Peak Voltage V |

|

|

Colour |

Number |

|

|

|

|

|

|

|

Blue |

M 820 |

8 |

800 |

20 |

|

|

25 |

|

Green |

M 1230 |

12 |

800 |

30 |

|

|

35 |

|

White |

M 550 |

5 |

800 |

50 |

50 |

10 |

55 |

|

White |

M 550 a |

5 |

500 |

50 |

30 |

10 |

60 |

|

White |

M 550 b |

5 |

100 |

50 |

7 |

10 |

70 |

|

Grey |

M 3100 |

3 |

800 |

100 |

30 |

10 |

110 |

|

Grey |

M 6100 |

6 |

800 |

100 |

30 |

10 |

110 |

|

Yellow |

M 2150 |

2 |

800 |

150 |

300 |

100 |

160 |

The diode bodies were offered in two different insulating materials with differing dielectric quality. In both cases inter-electrode capacity was low at only 1 pF and the diodes were suitable for frequencies up to 500 MHz. [Rost 1956]

These diodes were promoted to the German electronics industry by the company’s new commercial director, Dr Rolf Wiesinger. But the primary objective for Intermetall was exports so the company wrote to the National Scientific Laboratories in regard to US Government requirements (such as military applications). The reply was not very encouraging other than to note that if Intermetall could produce low noise diode mixers for 700 MHz then they would be interested.

These diodes were promoted to the German electronics industry by the company’s new commercial director, Dr Rolf Wiesinger. But the primary objective for Intermetall was exports so the company wrote to the National Scientific Laboratories in regard to US Government requirements (such as military applications). The reply was not very encouraging other than to note that if Intermetall could produce low noise diode mixers for 700 MHz then they would be interested.

Diode outline from Funkschau 1953, 18

Intermetall began journal advertising in the USA as this example from Electronics October 1953 illustrates. Note the anticipation of new semiconductors such as silicon and intermetallic compound semiconductors.

First Transistors

The first transistors Intermetall produced were their GSN1 and GSN2 point-contact types both for general purpose use in audio and radio circuits. In their early form they were produced as double ended devices following the same outline as the M series diodes (at the base lead end).

Right outline of the GSN type from Rost 1956. Left captured from a picture of the Intermetall stand at the Dusseldorf Exhibition courtesy R Herzog

The following data was published at the time of the Dusseldorf Exhibition from August 29th 1953:

|

Characteristics of Intermetall Point-contact Transistors |

||||

|

|

|

GSN1 |

GSN2 |

|

|

Four Pole Impedances |

R11 |

220 |

320 |

Ω |

|

R21 |

35 |

45 |

kΩ |

|

|

R22 |

20 |

25 |

kΩ |

|

|

R12 |

70 |

130 |

Ω |

|

|

Current Gain |

α |

1.8 |

1.8 |

|

|

Max Voltage Gain |

β |

160 |

140 |

|

|

Stability Coefficient |

δ |

≤0.6 |

0.6-0.9 |

|

|

Emitter Current |

IE |

+0.7 |

mA |

|

|

Input Impedance |

RI |

200 |

Ω |

|

|

Collector Voltage |

VC |

-12 |

V |

|

|

Collector Current |

IC |

-3 |

mA |

|

|

Output Impedance |

RO |

10 |

kΩ |

|

|

Power Gain |

|

≥18 |

dB |

|

|

Source Möller 1953 |

||||

Data for the GSN2 from Reuber 1953

The transistors were hand assembled by adjusting the point-contacts under a microscope while monitoring the resulting transi stor characteristics. The point-contacts were then fixed in place with epoxy glue. These production technologies were expensive and the yield was very low. For example, in one day 1,360 transistors were produced but the yield was only 38 on-specification transistors. Production rates of this order had also seen in the USA a year earlier. For example, mid 1952 Raytheon produced only 1000 point-contact transistors per month after four years R&D. [Radio Electronics July 1952]

stor characteristics. The point-contacts were then fixed in place with epoxy glue. These production technologies were expensive and the yield was very low. For example, in one day 1,360 transistors were produced but the yield was only 38 on-specification transistors. Production rates of this order had also seen in the USA a year earlier. For example, mid 1952 Raytheon produced only 1000 point-contact transistors per month after four years R&D. [Radio Electronics July 1952]

Transistor Characteristics instrument [Möller 1953]

Two point contacts of a germanium transistor. For clarity, the electrode spacing is 50μ not the normal 10μ [Mataré 1954]

A price sheet from Intermetall dated September 1, 1953 listed their two germanium transistors. The GSN1 sold for DM15 and the GSN2 was priced at 12 DM.

Deutsche Funkausstellung: German Radio Exhibition 1953

The Deutsche Funkausstellung had been held annually in Berlin since 1924 until the outbreak of World War II. In 1950 the Exhibition resumed in Dusseldorf and again in 1953 from the 29th August to the 6th of September. [IFA 2013] Its focus was the radio and television industries: components were not the primary purpose.

But In 1953, the timing and location was perfect for Intermetall and they mounted substantial exhibition with a strong emphasis on their new point-contact transistors. Expectations were high. Across the Atlantic the March edition of Fortune Magazine had described 1953 “the year of the transistor.” In the USA point-contact transistors were made by many producers but junction transistors were then only commercially available from Raytheon. However, several other USA companies announced junction transistors through the remainder of 1953.

A Radio Mentor reporter wrote from the Dusseldorf Exibition:

“Engineers were curious to assess the expected progress in transistors from the developments in the laboratories of Siemens und Halske, Telefunken and TeKaDe with examples of point-contact transistors as amplifiers and switches. At SAF the VS200 point-contact transistor was shown. Intermetall, which is under the technical and scientific direction of Professor Mataré, featured semiconductors exclusively. They fabricate various germanium diodes and point-contact transistors. Their research programme also covers wide ranging physical and chemical questions in semiconductors as well as intermetallic diodes that are particularly suitable for very short wavelengths.” [Reuber 1953]

Generous coverage of Intermetall was also featured by Funk Technik in an article by C. Möller, “Deutsche Transistoren,” who began by noting that “The transistor now seems to have passed the stage of a component with interesting physical properties, as it begins to carve out a number of applications that were previously exclusive to the electron tube.” The article draws extensively on Intermetall’s production technology and testing instrumentation. [Möller 1953]

Intermetall Stand at the Dusseldorf Radio Exhibition. Picture licensed by AIP Emilio Segre Visual Archives, Gift of Herbert Mataré

The front of the stand featured one of Intermetall’s many germanium diode characteristics instruments. It is shown in use in the Intermetall diode assembly and testing hall in a picture on the back wall of the stand.

On the right hand side at the rear of the stand a similar instrument for determining transistor characteristics was displayed.

Intermetall Stand at the Dusseldorf Radio Exhibition. Picture licensed by AIP Emilio Segre Visual Archives, Gift of Herbert Mataré

In another part of the stand a large mural of an Intermetall GSN type transistor provided a backdrop. In front a woman demonstrated one of three transistor receivers on show: a 30MHz receiver mounted in a plexiglass case powered with a hearing aid battery with earphone output intended as an in-ear monitor for use on stage. The device comprises a simple tuned diode detector stage tuned using a trimmer capacitor adjacent to the antenna followed by a three stage transformer coupled AF amplifier.

Below is a close up of the monitor [Mataré archives courtesy R Herzog]

The Funk Technik article illustrated two other receivers on display: both medium wave four transistor radios able to power a loudspeaker. One was designed as a portable set using a 30 volt hearing aid battery (left) and on the right a compact set for mains operation. The insert shows this set viewed from the front. [Möller 1953]

Above the schematic for the two Intermetall medium wave receivers shown at the Exihibition[Möller 1953]. Note the base of the first transistor should be grounded through the tuned circuit.

These sets were designed by Georges Calon who had developed a similar receiver while at CFS Westinghouse which had been shown at the Paris Salon National de la Pièce Détachée in 1952. Referring to the Westinghouse design Calon says “the sensitivity is quite high and it can receive the current European stations like London, Moscow and different Central European countries, not to mention many local stations, all on a normal indoor antenna.” [Calon 1952]

|

Commercially Available German Transistors by the Fall 1953 GSN1 and GSN2 from Intermetall. GT10, GT20 and GTA from Kristalloden VS200, VS220 and VS221 from SAF TS13 and TS33 from Siemens These were all point-contact types except the GTA. [Möller 1953] |

Just prior to the Dusseldorf Exhibition, Intermetall promoted Rolf Wiesinger who became its new Managing Director.

New Products in 1954

In 1954 Intermetall released a range of hermetically glass sealed diodes and radio frequency versions in the GSN point-contact range.

Glass Diodes

Intermetall supplemented its original ceramic range with 11 types in a hermetically sealed glass enclosure. The numbering system followed the USA JETEC types where, for example, the “1N34a” diode was offered as a “34a M” by Intermetall. They were colour coded as indicated in the table below.

|

Table of New Intermetall Glass Diodes |

||||||||

|

Type |

Continuous Reverse Voltage |

Forward Current at 1 V |

Typical forward Current |

Max Current |

Reverse Current |

At Reverse Voltage |

Colour Ring |

|

|

|

Max V |

Min mA |

Max mA |

mA (1 Sec) |

µA |

V |

Outer |

Inner |

|

M 34a |

60 |

5 |

50 |

500 |

30 (500) |

10 (50) |

Orange |

Yellow |

|

M 38a |

100 |

4 |

50 |

500 |

5 (500) |

3 (100) |

Orange |

Gray |

|

M 51 |

50 |

2.5 |

25 |

- |

1660 |

50 |

Green |

Brown |

|

M 54a |

50 |

5 |

50 |

500 |

7 (100) |

10 (50) |

Green |

Gray |

|

M 55 |

150 |

3 |

50 |

500 |

300 (800) |

100 (150) |

Green |

Green |

|

M 56 |

40 |

15 |

60 |

1000 |

300 |

30 |

Green |

Blue |

|

M 60 |

25 |

- |

40 |

500 |

30 |

1.5 |

Blue |

Black |

|

M 69 |

60 |

5 |

40 |

400 |

50 (850) |

10 (50) |

Blue |

White |

|

M 70 |

100 |

3 |

30 |

350 |

25 (300) |

10 (50) |

Violet |

Black |

|

M 81 |

40 |

3 |

30 |

350 |

10 |

10 |

Gray |

Brown |

|

M 95 |

60 |

10 |

50 |

500 |

800 |

50 |

White |

Green |

|

From Funkshau 1954 |

||||||||

Outline of the new Intermetal Glass Diode

New RF Point-Contact Transistors

Three new point-contact transistors were developed intended primarily for RF circuits with high current gain. The figure below shows good performance up to 10MHz (in the case of the GSN6).

Frequency response of the current amplification factor of the new intermetall GSN transistors

[Funkshau 1954]

The new transistors were offered in a single ended case that was 5.5 mm shorter than previously. The external body served as the base contact. This enclosure was also seen in surviving examples of the GSN1 and GSN2 shown below.

Surviving examples of the GSN1 or GSN2 appear always to be a second generation type with the three leads at one end. Picture courtesy R Herzog

GSN2 Picture courtesy of A Wylie. Note the lead colour coding (collector yellow and emitter red) missing from the GSN1 example.

New Compound Semiconductors

While he was at CFS Westinghouse, Mataré attended the first International Conference on Semiconducting Materials, held at Reading University from the 10th to the 15th July 1950. It attracted some 80 scientists from the United States, Holland, France, Denmark, Sweden, Italy, Spain and Germany. In addition, over 100 attended from universities and research laboratories in England. Very well know attendees included Dr William Shockley from Bell Laboratories, Professor Lark-Horowitz from Purdue University and Professor Nevill Mott from Bristol University all of whom were pioneers in semiconductor research.

In the dawn of wireless many minerals had been identified as useful point-contact detectors. For example, galena or mineral lead sulphide was a favourite. In the 1950 semiconductors were still in their infancy and producers had scarcely mastered germanium for point contact diodes and transistors.

The Reading conference reported recent work on characterising selenium, grey tin and black phosphorous and on compound semiconductors such as zinc oxide, lead sulphide, bismuth telluride and other compounds of silver, manganese and selenium. A prototype transistor using lead sulphide as the semiconductor was reported by C A Hogarth from Reading University. [Forsbergh 1950 Greenwood 2012 Hogarth 1950]

Mataré was inspired with what he learned there. Germanium was a rare element and therefore expensive. Silicon could not be purified with the technologies of 1950 and it would be another four years before the first silicon transistors were produced. Compound semiconductors offered the possibility of reduced costs and more convenient physical properties. On his return he discussed the possibilities with his colleague Heinrich Welker who was equally captivated.

Welker quickly began an investigation of the theoretical possibilities for these and early in 1951 made the first example compound from indium and antimony fusing them in a quartz boat to make crystalline indium antimonide. He confirmed that the material was a semiconductor. [Riordan 2004]

Welker approached Siemens and discussed the potential importance of III-V compounds with Professor Trendelenburg who was establishing the new Siemens-Schuckert research laboratories in Erlangen. Trendelenburg was enthusiastic and offered Welker a leadership role as head of the solid-state research division with the mandate to begin research into the III-V compounds as rapidly as possible. In due course this lead to pioneering patents issued to Welker and Siemens on the III-V compounds as semiconductors. Welker became internationally recognised as the pioneer of III-V compound semiconductors. [Welker 1976]

Welker resigned from Westinghouse on December 26, 1950 and began at Erlangen on April 1 1951 but it appears that the first experiments were unauthorised work at CFS Westinghouse. Mataré says the work was done in secret speculating that this was to avoid complications of ownership of the new intellectual property. Welker, however, says he began his laboratory work at Siemens. [Welker 1976]

III-V Semiconductors at Intermetall

The primary objective for Intermetall had to be early revenues and in 1952 that could only mean germanium diodes and transistors even though the deficiencies of germanium were well understood. Silicon was the obvious alternative but its high melting point meant purification was very difficult.

It was expected that the Czochralski method could be used to make single crystal III-V compound semiconductors such as antimonides of aluminium, gallium and indium (antimony is a Group V element and aluminium, gallium and indium are Group III). Mataré was very hopeful these new materials would lead to the development of next generation diodes and transistors.

In particular it was thought that aluminium antimonide with a large band gap of 1.5 eV and a manageable melting point of 1060°C was a good candidate. However, it proved difficult to make single crystalline rods of aluminium antimonide and the material was sensitive to oxidation, breaking down into a black powder in moist air.

The first prototype diodes made from this material performed somewhat as expected and in some instances better than germanium diodes. For example, at very low voltages aluminium antimonide had a steeper characteristic and faster recovery time suggesting high-frequency applications.

At the time Mataré was well aware of the difficulties of commercialising III-V semiconductors but arguing the need for further research and development, he wrote in 1954 " there is the prospect that not only could we replace expensive and rare germanium, but produce “made to measure” semiconductors to very specific requirements.” [Mataré 1954]

Closure of the Laboratory

Attempting to be a market leader in III-V compounds was too ambitious for Intermetall. In Germany, Siemens was a formidable competitor and they had secured Welker and his foundation patent meaning that at best Intermetall would need a license from Siemens (without any right to expect one). Lastly they had a cooperative relationship with Eduard Justi, a distinguished German researcher in this field. Justi was founder of the Institute of Applied Physics at the Technical University (TH) of Braunschweig and carried out research in mechanisms of conduction in metals and semiconductors, thermoelectrics, fuel cells and solar cells. His academic work was commercialised through Siemens. Visiting Mataré, Justi tried to persuade him that III-V compound research was fruitless in the face of the overwhelming position of Siemens.

In fact, compound semiconductors were an academic curiosity in 1954. History shows that it would take another 20 years to see the first applications for compound semiconductors. Through the 1950s and 1960s silicon met every need from high performance discrete components to integration. Welker, celebrating 25 years of research from the perspective of 1976, wrote “Relatively early on in my practical work it became clear to me that the III-V compounds would not displace silicon from the areas in which it was already established, but would instead find application in the fields where the versatility of the band structure could be fully exploited Such applications are magnetically controlled devices, optoelectronic devices, and Schottky field effect transistors and Gunn diodes which extend the frequency range above 5 GHz. The total world sales of such components manufactured from III-V compounds now amount to more than $200 million per year and are expected to exceed $500 million in 1980.” [Welker 1976]

In the end reality overtook the Intermetall programme: To cut costs the laboratory was wound down from mid 1954 and closed during the sale of the company to Clevite.

Sale of Intermetall to Clevite

In his USA haven, Jakob Michael was assailed by US media commentary on the "German Problem" which covered the improbability of reunification, West Germany's evolution from an occupied territory to a re-armed sovereign state within NATO and the potential diabolical consequences of Cold War rhetoric disintegrating into battle. In the Far East the Korean War had just ended and an East-West conflict centred on Germany was plausible. He concluded his German investments were at risk.

German economic reforms had been remarkably successful. [IMF 1954] By the end of 1953 the Deutschmark was close to being freely convertible and for the first time Michael was in a position to sell up in Germany and transfer the proceeds to the USA. In December 1954 he sold DeFaKa to Helmut Horten GmbH for DM60m but selling a semiconductor start-up in its second year was a more difficult undertaking. Intermetall was making only slow progress towards commercial revenues. Intermetall either needed access to lucrative military markets in the USA or patience and deep pockets to await the consumer driven applications for transistors in Europe. Worse, Michael was also funding an ambitious research programme on silicon and III-V semiconductors (more appropriate for a technology giant such as Bell Laboratories).

Initially some interested parties were found but they were not willing to pay Michael’s asking price and the sale process became protracted. Key employees feared for the future of the company and left: Oskar Walter joined Siemens, Georges Calon went back to France and Herbert Mataré immigrated to the USA quite bitter that Michael had defaulted on his promise to give the company five years to become profitable.

In the summer of 1954 a serious problem emerged with existing stocks of transistors. Despite all the care that went into their production the transistors were found to have off-specification characteristics and were unsaleable. These transistors were not stable and had deteriorated in just a few months. This was probably due to the fact that Intermetall transistors were not hermetically sealed and relied on epoxy resin to protect the point-contact area. Other producers such as Raytheon also found that resin sealing was not moisture proof. [Burgess 2009]

In response to this calamity most employees were laid off in November 1954. A month later in the USA, Mataré gave a lecture at Transistor Products, a company owned by Clevite. Still a Director of Intermetall, Mataré was able to promote the sale of his company because he had with him photos of its facilities, data sheets and actual production samples.

Clevite Corporation was founded in 1919 as an engineering company and during the War had produced bearings for the aviation industry. Post War they entered the electronics market through the acquisition of Brush Development Corp in 1952 and Transistor Products in 1953. By 1954 Transistor Products was trading as Clevite Transistor Products specialising in germanium power transistors. [Knight J 2007]

Transistor Products expressed strong interest and a senior manager flew to Dusseldorf to visit Intermetall’s plant to assess it. He also requested 100 sample transistors from current production to take back to the USA. Stasek, Herbert Knabe and others that still remained at Intermetall worked until Christmas Eve 1954 to produce the required transistors, mount them and seal them into their cases. These were prototypes of their new alloy junction transistors, the OC33 and OC34 which were later announced in May. [Radio Mentor 1955 (1)]. Clevite were impressed with the quality of the transistors produced.

It was agreed that Michael would keep Intermetall going for a further six months and grant to Clevite  an option to buy. Transistor Products sent a team from the USA. The focus of company became manufacture, not research and the III-V compound semiconductor research lab was closed down.

an option to buy. Transistor Products sent a team from the USA. The focus of company became manufacture, not research and the III-V compound semiconductor research lab was closed down.

Figure: Advertising by Intermetall in Febuary 1955 during the sale process now including PNP and NPN junction transistors [Funkshau 3 1955]

By early 1955 Intermetall were able to mass produce the OC33 and OC34 alloy junction transistors in small volumes although the earliest public record of this appears to be in May of that year. [Radio Mentor 1955 (1)] The February advertisement mentions NPN transistor, most probably the OC24 which was shown at the Dusseldorf Exhibitionin August 1955 but never commercialised.

In May 1955 Intermetall produced miniature versions where the can was only 3.5 mm in diameter capping off a successful period of commercialisation of a respectable range of junction transistors.

At this time Clevite did not have comparable low power AF pnp junction transistors although they did have two AF npn transistors developed two years previously. These were the X-22 and X-23 in large format cans which had been part of the Transistor Products range since 1953. [Electronic Design 1953] They also had an extensive range of prototype power types. [Knight 2007] Thus Intermetall technology was attractive. Markets in the USA were also attractive with the first transistor radios appearing and established uses in more specialised applications such as hearing aids. Clevite therefore had good reason to exercise its option and they acquired Intermetall mid 1955. Mataré resigned from the Board and remained in the USA because it offered him more opportunities.

Clevite appointed Rudolf Sachs as the new Managing Director of Intermetall. He had immigrated to the USA as a German Jew in 1938 and gained experience in the mass production of transistors at Transistor Products. He oversaw a dramatic increase in production capacity with more than double the staff. But yields were low at only 1% and the solution was to hire more highly experienced staff. Georges Calon who has been the production manager 1952-54 was brought back from France and a man of the highest reputation in the industry, Karl Seiler, was recruited from the ITT German subsidiary company, Süddeutsche Apparate-Fabrik (SAF), early in 1956. Seiler had been responsible for the semiconductors development programme of SAF since 1948.

During this time Clevite invested over one million DM especially in new plant for alloy diode and transistor production.

New Junction Transistors

Intermetall produced the OC32 - OC34 series pnp transistors from February 1955. These were AF types with similar characteristics but differentiated by gain. An OC24 npn type was mentioned with mirror image characteristics of the OC34 for pairing in complementary output circuits. [Rost 1956]

Media news of the new Intermetall junction transistors was covered in the May 1955 edition of Radio Mentor. The OC32, OC33 and OC34 series of transistors were offered in metal cans 5x8x11 mm and a rating of 50 mW. They appear to be selected from production with increasing gain and frequency performance suggesting applications for audio through to intermediate frequency amplifiers. [Radio Mentor 1955 (1)]

Media news of the new Intermetall junction transistors was covered in the May 1955 edition of Radio Mentor. The OC32, OC33 and OC34 series of transistors were offered in metal cans 5x8x11 mm and a rating of 50 mW. They appear to be selected from production with increasing gain and frequency performance suggesting applications for audio through to intermediate frequency amplifiers. [Radio Mentor 1955 (1)]

A second miniature series was made from the same transistor elements with similar type numbers: OC320, OC330 and OC340. They were assembled in cylindrical cans 8.8 mm long and only 3.5mm in diameter. These had down rated power capacity to 35mw due to their smaller can size but otherwise had the same characteristics as the large format devices. Both types of transistors were mounted on glass headers.

Compared to their mainstream competitors Intermetall were a year behind. 1954 was the year of the junction transistor for audio applications. At the April 1954 Hanover Fair Telefunken announced its Alloy pnp types OC601 and OC602 and Valvo (Philips) announced its OC70 and OC71. Siemens showcased their TF70 series grown junction npn types. [Funk Technik 1954] However, by the end of 1955, Intermetall had caught up with the launch of one of the first European RF alloy junction transistors.

Picture: OC34 courtesy S Neumann Radiomuseum

|

Characteristics of the Intermetall Alloy Junction Transistors

|

|||||||

|

|

OC32 |

OC33 |

OC34 |

OC24 |

OC320 |

OC330 |

OC340 |

|

|

|

|

|

|

|

|

|

|

Type |

pnp |

pnp |

pnp |

npn |

pnp miniature |

pnp miniature |

pnp miniature |

|

Maximum Ratings

|

|

|

|

|

|

|

|

|

VC Volts |

25 |

25 |

25 |

Not in production. Characteristics mirror image of OC34 |

20 |

20 |

20 |

|

IC mA |

10 |

10 |

10 |

10 |

10 |

10 |

|

|

PC mW |

50 |

50 |

50 |

35 |

35 |

35 |

|

|

IE mA |

10 |

10 |

10 |

10 |

10 |

10 |

|

|

|

|

|

|

|

|

|

|

|

Typical Characteristics

|

|

|

|

|

|

|

|

|

Power Gain1 dB |

38 |

40 |

42 |

38 |

40 |

42 |

|

|

Frequency Cut-off2 MHz |

0.6 |

0.8 |

1.1 |

0.6 |

0.8 |

1.1 |

|

|

Footnote 1 in common emitter circuit VC = 5 volts IC = 1 mA RI = 600 Ω RO = 30 kΩ Footnote 2 in common base circuit |

|||||||

|

Source: Rost 1956 and Radio Mentor 1955 (2) |

|||||||

Intermetall Sales in the USA

The foundation business plan of Intermetall had been to produce diodes and transistors in Germany for sale in the USA. This had proven difficult because the US military had a strong preference for US made semiconductors and because up until 1954 transistors were bought more often for evaluation than practical application. With a US owner behind Intermetall and the development of new applications there was a least a credible opportunity to sell the new Intermetall transistors in the USA.

Soon after the purchase of Intermetall two of the new junction transistors (OC33 and OC34) were listed in the USA as part of the Clevite Transistor Products range. [Tele-Tech September 1955] This listing showed the value of the German acquisition to Clevite because at the time their general purpose range was very out of date. Other than the new Intermetall transistors it consisted of:

Soon after the purchase of Intermetall two of the new junction transistors (OC33 and OC34) were listed in the USA as part of the Clevite Transistor Products range. [Tele-Tech September 1955] This listing showed the value of the German acquisition to Clevite because at the time their general purpose range was very out of date. Other than the new Intermetall transistors it consisted of:

Two grown junction transistors (X-22 and X-23) first introduced in 1953 as experimental types

Twelve out-dated point-contact types 2A, 2C, 2D, 2,E 2G, 2H, 2N32, 2N33, 2N50, 2N51, 2N52 and 2N53

Their range of experimental power types X102, X107, X120, X122 and X125

Picture Courtesy Rudi Herzog: the OC33 and OC34 were sold by Transistor Products in the USA

In a reciprocal move, Intermetall added the Clevite Transistor Products power transistors to their range in Germany and featured them at about the same time at the Dusseldorf Exhibition.

Dusseldorf Exhibition 1955

The Deutsche Funkausstellung was held in Dusseldorf in 1955 from 28th August to 4th September for the last time. In 1957 it moved to Frankfurt for that year and 1959 before relocating to Berlin in 1961. [IFA 2013]

Lennartz reporting for Funk Technik noted some significant transistor trends in two directions: towards power transistors in the audio range and RF transistors operable up to 2-3 MHz. He noted point-contact transistors were virtually out. Diodes featured higher reverse voltages, use of silicon and power rectifiers were seen. He advocated caution, however, noting that the power transistors were really still in pre-production with limited availability and RF transistors even less developed. Never the less the overall report was optimistic with a forecast of even greater innovations in the future. [Lennartz 1955]

The Exhibition celebrated a billion DM industry with exports 30% of the total: a clear indication of the success of the post-War industrialisation of Germany. Over 200 manufacturers had stands. Other semiconductor manufacturers were there too but not primarily to feature diodes and transistors. For example, Telefunken, Valvo and Tekade were in the Radio and Television Hall. Siemens were located in the Radio and Television Equipment Hall (Maschinenhalle (Funk- und Fernsehindustrie).

Intermetall were in the Components Hall. [Funk Technik 17 1955]

As in 1953, the timing was perfect for Intermetall and this Fair served as an effective platform to re-launch the company following its poor fortunes in 1954. It had overcome the reputational damage from the closure of its III-V laboratory and the departure of its founding scientist and Director, Herbert Mataré along with other key staff. Post the take-over by Clevite and new management, it was able to showcase its new alloy junction transistors, miniature transistors, RF transistors, new silicon junction diodes and the range of power transistors now available from Clevite Transistor Products.

General Purpose Alloy Junction Transistors

Intermetall had already released all details of its general purpose alloy transistors four months earlier in May. Lennartz repeated Intermetall’s claim that their miniature types were “referred to as the smallest transistor in the world” and noted that Intermetall had added the OC360 to the range of miniature transistors previously announced. [Lennartz 1955]

To showcase its alloy junction range, Intermetall showed a four transistor transformerless 200mW record player amplifier featuring complementary pair of transistors in the output stage. The output transistors were their pnp type OC34 and OC24, a developmental npn transistor. [Radio Mentor 1955 (2)]

Complementary pair Phonograph Amplifier Using Intermetall Transistors [Radio Mentor 1955 (2)]

Other AF applications such as hearing aids were noted.

RF Transistors

In addition to the AF range Intermetall showed an RF transistor, the OC390 with a power gain of 30 dB at 455 kHz and performance up to 3 MHz making it suitable for the RF and IF stages of a medium wave AM portable or automotive radio.

In order to obtain high frequency performance its collector-base

In order to obtain high frequency performance its collector-base capacitance was very low (7 pF), while the emitter capacitance as well as the intrinsic base resistance were also minimised. [Lennartz 1955]

capacitance was very low (7 pF), while the emitter capacitance as well as the intrinsic base resistance were also minimised. [Lennartz 1955]

Typical operating conditions were VCE of 5 volts and an emitter current of 1 mA. [Richter 1956] This later reference gives the typical base emitter capacitance as being higher at 13pF. It was noted that even higher frequency transistors could be selected from production. By 1956 this first transistor evolved into a range performing up to 10MHz.

To illustrate an application using this transistor, Intermetall modified a Regency TR1 receiver replacing the Texas Instruments npn transistors with the new Intermetall RF and AF transistors with associated circuit modifications. Long term this transistor was not hugely successful. The Radiomuseum database shows it was used in only 11 receivers as an IF amplifier. By way of comparison, the well known OC45 transistor designed for IF duty is listed in nearly 700 transistor radios.

Picture Left: Intermetall OC390 courtesy J Röhling, Radio Museum

Picture Right: library shot of the Regency TR1 made in the USA by the Regency Division of IDEA Corporation released for Christmas 1954.

[Ref Funkshau 16 1955, Lennartz 1955, Radio Mentor 1955 (2)]

Power Transistors

Intermetall demonstrated three power transistors that were part of the Transistor Products range and now available to them as a sister company through Clevite. These were

X-125 for 3 W maximum power dissipation;

X-122 for 7.5 W; and

X-120 for 15 W.

Further information on the development of the Transistor Products power transistor range can be found at the Transistor Museum [Knight 2007]

Using the X-120 an undistorted output of 30W could be achieved using two X-120 in a class B output stage. [Funkshau 16 1955 p341] Now for the first time fully transistorised automotive receivers could be constructed from Intermetall RF and AF transistors. Other applications noted were in switching and control technology, power supplies and inverters provided such applications could sustain the high price of these power transistors. [Lennartz 1955]. Apart from the matter of cost, the exceptionally large size of the X-120 would limit applications.

Picture courtesy J Knight of Clevite branded power transistors: X125, X122 and X120 (left to right) with insert showing typical internal geometry

This picture shows the relative scale of all the Intermetall alloy junction transistors. This makes it clear that the basic transistor element for all the power transistors is closely related to the X-125 and that a large measure of the improved dissipation is due to the oversized cooling fins. [Picture Lennartz 1955]

Ratings for the power transistors is given in the following table. Note the differences in input or output impedances across the range showing these transistors are not identical.

|

Characteristics of Intemetall Power Transistors

|

||||

|

Maximum and Operating Ratings |

X-120 |

X-122 |

X-125 |

Unit

|

|

Collector Voltage |

-60 |

-60 |

-60 |

Volt |

|

Collector Voltage (operating_ |

-30 |

-30 |

-30 |

Volt |

|

Collector Current |

-4 |

-4 |

-1 |

Amp |

|

Collector Current (operating) |

-1 |

-1 |

-0.3 |

Amp |

|

Power at 25 C and VCE 30 volts |

15 |

7.5 |

31 |

Watt |

|

|

|

|

|

|

|

Input Impedance |

800 |

900 |

1500 |

Ω |

|

Output Impedance |

70 |

150 |

375 |

kΩ |

|

|

|

|

|

|

|

|

|

|

|

|

|

Note 1: If screwed onto the chassis, otherwise 1.2 W Source Lennartz 1955, Tele-Tech September 1955 |

||||

Radiation Detector

In a further example of applications that made use of the portability of transistorised equipment, a Geiger counter was shown with a transistor power supply for its tube and two transistors in its monitor circuit. [Radio Mentor 1955 (2)]

|

Other German junction transistors in Lennartz Dusseldorf Report

SAF OC110 , OC120 and OC130 Siemens brought a pnp junction transistor TF65 for use in hearing aids in addition to their existing NPN types TF 70 , TF 71 and TF 72 TeKaDe GFT2006 power transistor and the small signal type GFT20 Telefunken OC601 OC602 and OC603 and OC604 Valvo OC15 OC70 , OC71 and OC72 |

Germanium power rectifiers

The Dusseldorf Exhibitionfeatured germanium junction power rectifiers offered by Intermetall and SAF. The Funk Technik report from the show pointed out that because of their very low forward resistance of only 1-2 Ω these rectifiers could be used in power supply circuits with relatively high power outputs. The SAF units were DF 450, DF 451 and DF 452 and could handle forward peak currents similar to the Intermetall product but Intermetall rectifiers had a superior reverse voltage performance. [Lennartz 1955]

The Intermetall range were JEDEC registered types originally developed by General Electric in 1952. The use of JEDEC type numbers suggests that they could well have been imported from the USA where they were produced by many companies.

|

Characteristics of the 1N91-93 Series Rectifiers

|

|||

|

|

1N91 |

1N92 |

1N93 |

|

PIV max Volts |

100 |

200 |

300 |

|

Peak current Amps |

0.47 |

0.31 |

0.28 |

|

Working Voltage |

30 |

65 |

100 |

|

Forward voltage max current |

0.5 |

0.5 |

0.5 |

|

Forward resistance Ω |

1.1 |

1.5 |

1.9 |

|

Temperature rating 0C |

55 |

55 |

55 |

|

Source Lennartz 1955 |

|||

Silicon Junction Diodes

Possibly the most significant development by Intermetall released at the Dusseldorf Exhibitionwas their silicon junction diodes although these did not make the headlines in the German technical press.

Intermetall introduced their S21, S22, S23 and S24 types which could be operated at temperatures up to 150oC (much higher than possible with germanium). They were low powered devices with a relatively high forward resistance (they would pass only 1 mA at 1 Volt forward potential). [Lennartz 1955] These diodes appear to have been released just in time for the Exhibition. [Intermetall 1955]

Within a few months these diodes were replaced by a new series: the S 32, S 33, S 34, and S 35.  These had a much better forward characteristic passing 20 ma at 1 volt [Lennartz 1956] indicating the premature range released for the Exhibition were actually early prototypes. An Intermetall price list from March 1956 showed that they were priced from 12 DM to 21 DM (S 32 to S35 respectively).

These had a much better forward characteristic passing 20 ma at 1 volt [Lennartz 1956] indicating the premature range released for the Exhibition were actually early prototypes. An Intermetall price list from March 1956 showed that they were priced from 12 DM to 21 DM (S 32 to S35 respectively).

The full story of the development of Intermetall silicon devices is told in the following chapter.

Development of Silicon Devices

The advantages of silicon were well understood by the semiconductor industry and prior to the emergence of modern diffusion technologies and integrated circuits, were largely seen in terms of its superior high temperature performance and lower leakage currents compared to germanium.

But its very high melting point made the production of high purity single silicon crystals very difficult. This is something that Mataré was very well aware of having worked on silicon point-contact detectors for radar at Telefunken during the War. Thus in setting up the Research and Development laboratory at Intermetall, Mataré initiated work on the purification of silicon installing vacuum silicon pulling equipment.

Although the first commercial silicon transistors made were grown junction types produced by Texas Instruments in 1954, this was a difficult technology to master for mass production and most companies opted for the alloy junction approach pioneered in the development of germanium junction transistors and diodes. Ultimately diffusion technologies prevailed almost entirely based on the work at Bell Laboratories from around 1954 onwards.

Appointment of Karl Seiler

Clevite sought a high profile German physicist to restore the reputation of Intermetall following the departure of Mataré. They secured Karl Seiler, anexpert in silicon semiconductor technology and the production of diodes and transistors.He was appointed to accelerate the introduction of silicon technology and mass production of silicon diodes and transistors.

During the War Seiler had worked at Telefunken on silicon radar detectors (as did Mataré). In 1942 he measured the energy gap to the conduction band in germanium and silicon, an important observation that confirmed the intrinsic semiconducting property of these materials. (The conventional view was that semiconduction was an artefact of impurities present and that there were no common pure semiconductors.) [Seitz 1998]

After the War he set up a small facility in Mönchberg and produced silicon detectors for use in multiplexed telephone circuits. During this time he developed a silicon junction diode using a development of the diffusion technology first used at Telefunken as part of their radar detectors programme. In 1948 demand had outgrown his production capacity and he accepted a proposal to join Süddeutsche Apparate-Fabrik (SAF) as its laboratory manager and transfer his production to them.

Seiler left SAF and moved to Intermetall in March 1956. There he articulated a new strategy: Intermetall would no longer be a pioneer but a “fast follower,” an approach he hoped would preserve capital and save costs.

Information on how Intermetall developed silicon devices is disclosed in Seiler’s book Physik und Technik der Halbleiter which draws extensively on material sourced from Intermetall.

Forming Silicon PN Junctions

The key issues that had to be solved related to finding an alloy dot composition that minimised thermal mismatch strains while permitting good wetting of the base tab. [Burgess 2009, Burgess 2012] Given the solution to these issues, the production of junction diodes was then reasonably straightforward because diode performance did not depend on alloying depth. (The dilemma associated with both alloy junction and grown junction transistors was controlling the base width.)

Intermetall developed an unusual approach to creating PN junctions using aluminium wire as the alloying agent. This is illustrated in the simplest case for the formation of a silicon junction diode.

Here a wafer of N type silicon is placed in an alloying jig on gold foil which was doped with an N type impurity such as 1% antimony. The two parts were held together with a weighed ring through which an aluminium wire could be introduced and positioned on the silicon wafer. Each production jig held many inserts.

Here a wafer of N type silicon is placed in an alloying jig on gold foil which was doped with an N type impurity such as 1% antimony. The two parts were held together with a weighed ring through which an aluminium wire could be introduced and positioned on the silicon wafer. Each production jig held many inserts.

The entire assembly was heated to 650-700 °C for a few minutes in a tunnel oven under a hydrogen atmosphere. This resulted in an alloyed insert: a PN junction formed on the upper surface. The doped gold formed an ohmic contact with the bottom surface of the silicon. These layers are illustrated in the cross sections of a finished diode:

Left: alloyed insert soldered on a diode base. Right: Cross section through the PN junction and base plate. [Seiler 1964]

An exploded view of a complete diode is shown on the left [Seiler 1964] and on the right an Intermetall OY 6041 Silicon Diode [Richter 1958]

Alloy Silicon Transistor

Silicon transistors were made in a similar manner. The components of the transistor insert were  assembled in suitable jigs. The connection to the base layer was made by a gold antimony ring that ensured an ohmic connection.

assembled in suitable jigs. The connection to the base layer was made by a gold antimony ring that ensured an ohmic connection.

The emitter and collector could be aluminium wires as shown in the cross section below or aluminium dots could be utilised.

While care was taken in the choice of materials to minimise stress cracking caused by thermal mismatches, this remained a problem for alloy transistors made this way. Silicon alloy junction technology did not survive the advent of silicon diffusion semiconductors that could meet every need for many decades to come. [Seiler 1964]

Above: Photomicrograph of the cross section of an Intermetall silicon alloy junction transistor [Seiler 1964]

By August that year the first fruits of Seiler’s work were seen in Intermetall’s advertising in Funkschau: Intermetall was the first German company to produce a silicon transistor.

Advertising in August 1956 made it clear that Intermetall now had a complete range of  semiconductors: RF transistors of very respectable performance, silicon junction diodes announced nearly a year ago and now silicon transistors.

semiconductors: RF transistors of very respectable performance, silicon junction diodes announced nearly a year ago and now silicon transistors.

In November the new silicon range was comprehensively covered by Funktechnik in an article headlined “First German Silicon Transistors” that noted “While silicon transistors have been on the market in the USA for quite some time, Intermetall is the first German company producing pnp silicon junction transistors. There is a complete series: OC 430, OC 440, OC450, OC460 and OC470 for various applications. These transistors are not set to replace the germanium types, but should be used everywhere reliable performance is required at high ambient temperatures.” [Funk Technik 1956]

Originally these transistors were released as the OC43, OC44, OC45, OC46 and OC47 series but were re-named because Valvo had priority on these type numbers for their alloy junction germanium range. [Gebert 2014]

Above: Intermetall advertising in August 1956 [Funkschau 1956]

|

Intermetall Silicon Transistors

|

||||||

|

Typical Characteristicsin Common Emitter Circuit measured at VCE = -5V, IE = 1mA, f = 1000Hz |

OC430 |

OC440 |

OC450 |

OC460 |

OC470 |

Unit |

|

h21E |

10…20 |

10…20 |

>10 |

>20 |

>20 |

|

|

h22E |

36x10-6 |

36x10-6 |

110x10-6 |

145x10-6 |

145x10-6 |

S |

|

h11E |

900 |

900 |

1400 |

1700 |

1700 |

Ω |

|

h12E |

0.4x10-4 |

0.4x10-4 |

0.65x10-4 |

0.75x10-4 |

0.75x10-4 |

|

|

Cut-off frequency common base fαCO |

1.8 |

1.8 |

1.8 |

6 |

6 |

MHz |

|

Collector capacitance CCB |

21 |

21 |

21 |

21 |

21 |

pF |

|

|

|

|

|

|

|

|

|

Maximum Values |

|

|

|

|

|

|

|

Collector Voltage -VCB max (IE = 0) |

10 |

30 |

75 |

10 |

30 |

V |

|

Peak Voltage –VCE max (IB = 0) |

10 |

30 |

75 |

10 |

30 |

V |

|

Collector Current –IC max |

50 |

50 |

50 |

50 |

50 |

mA |

|

Collector leakage current at |

|

|

|

|

|

|

|

-VCE = 10V. IB = 0 (typical and max) |

≈5 (<100) |

|

|

≈5 (<100) |

|

nA |

|

-VCE = 10V. IB = 0 (typical and max) |

|

≈0.4 (<2) |

|

|

≈0.4 (<2) |

μA |

|

-VCE = 10V. IB = 0 (typical and max) |

|

|

≈0.4 (<2) |

|

|

μA |

|

PC+ PE ( tamb = 100oC ) |

200 |

mW |

||||

|

tj max |

150 |

oC |

||||

|

Temperature range |

-40 to +150 |

oC |

||||

|

1/χ |

4 |

mW/oC |

||||

|

Data from Funk Technik 1956 |

||||||

The new transistors could operate at 150°C and were offered in hermetically sealed “subminiature” cans. They were some five times more expensive than the Intermetall germanium types. [Walter Arlt 1957]

In the USA, Clevite Transistor Products moved fast to take advantage. It submitted preliminary datasheets dated 8th August 1956 to JEDEC seeking registration of the five transistors in a series 2N260-2N262A. [JETEC 1956] The Clevite transistors were packed in a similar outline can: slightly fatter but shorter than the Intermetall outline.

These were electrically equivalent to the Intermetall range as shown in the table below.

|

Clevite Transistor Products Range of Silicon Transistors

|

Outline |

|||||

|

Intermetall Type |

OC430 |

OC440 |

OC450 |

OC460 |

OC470 |

5mm Ø 8 mm high |

|

Clevite Type |

2N260 |

2N260A |

2N261 |

2N262 |

2N262A |

6.4mm Ø 7.2 mm high |

The new Clevite transistors were seen in a transistor specifications listing in the December 1956 edition of Tele-Tech magazine. [Tele-Tech 1956]

In a similar manner Internetall devices were sold via the Brush wing of the Clevite group: Brush crystal in England sold the “S” diode range rebranded with their logo:

Intermetall Brush Crystal branded S 35 Silicon Diode (courtesy Jan De Groot)

Zener Diodes

The new Intermetall silicon diodes (S 32 to S 35) had a very pronounced Zener characteristic as shown in the left hand side of the plot of reverse voltage and current. [Lennartz H 1957 (3)]

The new Intermetall silicon diodes (S 32 to S 35) had a very pronounced Zener characteristic as shown in the left hand side of the plot of reverse voltage and current. [Lennartz H 1957 (3)]

By suitable control of doping levels, the Zener breakdown voltage could be reduced to less than 10 volts as in the case of the first series of Zener diodes (Z6 to Z8) produced by Intermetall:

Intermetall was the first German company to produce Zener diodes. [Lennartz 1957 (3)] They were produced in the same manner as the rectifying diodes described above [Seiler 1964] and packaged in a similar outline to the “S” series silicon rectifiers

The diodes were mounted on a glass and metal header and hermetically sealed to a metal can.

hermetically sealed to a metal can.

Seiler regarded this development as a very good example of being a fast follower: Intermetall did not invent the Zener diode but by being first in Germany they established an attractive niche market in which they could maintain a leading position both in Germany and globally.

Picture from Intermetall Advertisement in Kristalldioden und Transistoren Taschen Tabelle 1958. Diode outline from Lennartz 1957 (3)

Left: Characteristics of the new Intermetall Zener Diodes [Lennartz H 1957 (3)] Right: Silicon Zener diode shown on the title page of a prospectus of Intermetall 1959.

New Power Transistors 1957

Early in 1957 Intermetall introduced the new range of germanium PNP power transistors made by Clevite Transistor Products in the USA. These were all in the modern TO3 outline with a recessed evacuation pip visible in the picture (left).

Early in 1957 Intermetall introduced the new range of germanium PNP power transistors made by Clevite Transistor Products in the USA. These were all in the modern TO3 outline with a recessed evacuation pip visible in the picture (left).

The new transistors were:

2N257 and 2N268 and

CTP1104, CTP1108, CTP1109 and CTP1111 [Lennartz 1957]

These were all rated at 15 Watts but for a range of maximum collector voltages and amplification factors.

The 2N257 and 2N268 had been released by Clevite in the USA late the previous year (September and December, respectively). They were Germanium PNP devices designed for AF power output stages capable of 25 Watts with a suitable heat sink. [JETEC 1743 JETEC 1804]

The CTP series were similar Germanium PNP power transistors also rated for 25 Watts. They were introduced at around the same time. (Note the maximum collector dissipation for the Clevite and Intermetall versions would be expected to be identical.)

New Rectifiers 1957

At the Hannover Fair in 1957 Intermetall announced new silicon Zener diodes and silicon power rectifiers. SAF announced silicon rectifiers and both Siemens and Telefunken had also developed Zener diodes. Silicon rectifiers offered improved operating temperatures and reverse voltages at the expense of forward resistance when compared to germanium rectifiers. [Lennartz 1957 (2)]

|

Characteristics of Intermetall Silicon Rectifiers

|

||||

|

Type |

Peak Reverse |

Forward |

Forward Characteristics |

|

|

|

Voltage V |

Current Max A |

Current A |

Voltage V

|

|

OY6041 |

100 |

1.0 |

0.35 |

1.5 |

|

OY6042 |

200 |

1.0 |

0.35 |

1.5 |

|

OY6043 |

300 |

1.0 |

0.35 |

1.5 |

|

OY6044 |

400 |

1.0 |

0.35 |

1.5 |

|

OY6045 |

500 |

1.0 |

0.35 |

1.5 |

|

OY6046 |

600 |

1.0 |

0.35 |

1.5 |

|

OY6047 |

700 |

1.0 |

0.35 |

1.5 |

|

Data from Lennartz 1957(2) |

||||

Advertised Range in 1957

Intermetall Range advertised in Funk Technik August 1957. Graphic has been split in two parts. Left: top of the advertisement. Right: bottom of the advertisement

Intermetall Factory Operations in 1958

The following pictures illustrate factory operations in 1958 [courtesy R Herzog]

Large numbers of female workers were used in all aspects of processing and testing

Delicate operations such as soldering leads to transistor alloy dots were carried out with the aid of binocular microscopes

Left: Alloy dots were punched out of metal foil. Right: assembly of components for 40 transistors in a jig prior to alloying in a tunnel oven

Some operations were undertaken in a glove box to protect sensitive parts from the atmosphere

Brush Clevite Company

The British company, Brush Crystal Company Ltd of Hythe, Southampton, was taken over by Clevite and ultimately renamed Brush Clevite. [Lake 1976]. This company is best known for producing  magnetic tape recorders and piezoelectric transducers such as headphones or microphones.

magnetic tape recorders and piezoelectric transducers such as headphones or microphones.

In 1962 it had a flourishing semiconductor division largely making silicon devices employing 320 persons across all its divisions. [New Scientist 1962]

As part of the Clevite group it sold Intermetall semiconductors under its own brand using a logo related to that of Intermetall (using a “B” inside a small diamond as shown in the picture (right) of an OC470).

An interesting example of Brush transistors is the OC700-OC704 series which was introduced and withdrawn relatively soon. It appears to be of Intermetall manufacture. They were a series of silicon alloy PNP 300mW transistors for mixed applications current in the early 1960s. Picture and data courtesy Andrew Wylie

An interesting example of Brush transistors is the OC700-OC704 series which was introduced and withdrawn relatively soon. It appears to be of Intermetall manufacture. They were a series of silicon alloy PNP 300mW transistors for mixed applications current in the early 1960s. Picture and data courtesy Andrew Wylie

Inter-firm Comparison at the end of the 1950s

With the advent of the mass production of medium wave band capable transistors by Valvo (OC44, OC45) and Telefunken (OC613, OC612) in 1957, full transistor receivers were now made and sold. In 1959 a survey published by Funk Technik covered 11 manufacturers and 43 portable receivers that they produced. Of these 25 were “all transistor” and three used transistors in the audio stages. Valvo or Telefunken semiconductors dominated and no Intermetall transistors were listed. [Funk Technik 6 1959]

The first fully FM capable transistors (Valvo OC170 and Telefunken OC614) were advertised in 1958.

The first West German FM fully transistorised portable radios were the Neckermann 920/30 and the Südfunk K986, both manufactured by Südfunk. Two Telefunken OC615 transistors were used in the FM Tuner.

In the spring of 1959 other German FM portables were still equipped with battery tubes. It was not until the middle of the year that all transistor FM receivers were produced by Grundig, Philips, Schaub-Lorenz and Telefunken.

The Valvo OC170 was a germanium diffused pushed out base design developed within the Philips group. Telefunken adopted diffused drift germanium technology. Diffused devices enabled higher frequency performance but at this time Intermetall was not competitive.

The following table confirms the leadership position of Intermetall in silicon transistors. It had been the first to market in 1956 and remained ahead at the end of the decade. It had not invested in diffusion and therefore lagged behind on high frequency performance.

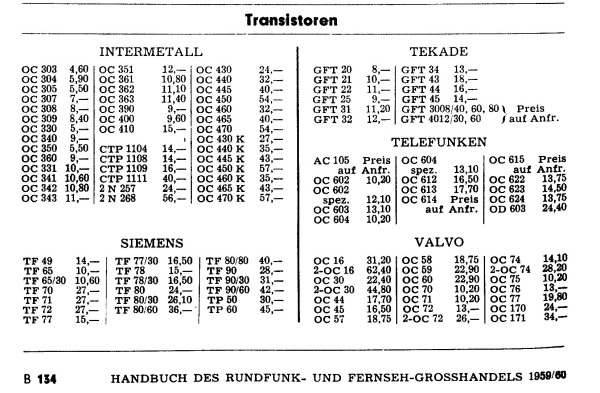

German Producers Semiconductor Range 1959 from Handbuch des Rundfunk- und Fernseh-Grosshandels 1959/60

A New Decade: Intermetall in the 1960s

In 1960 the German economy was booming. Production increased on all fronts especially in consumer goods. Manufacturers struggled to find workers to keep pace with the demands of production.

Intermetall was now a successful company and needed to expand its capacity. It first looked for new sites in Dusseldorf but could not find anywhere suitable. Instead, it opted for the South Baden region which offered the advantage of low cost labour: something important given the highly manual nature of every step in the production of semiconductors.

In mid 1958 Seiler decided to move the company to Freiburg and early in 1960 was fully established there. At this time the company employed 730 persons.

At the same time, Clevite had also bought the Shockley Transistor Corporation, thus creating strong ties with Silicon Valley in California. This company had been formed by William Shockley to develop the PNPN switch and had silicon diffusion technologies originally transferred from Bell Laboratories.

Despite its brief ten year history, Intermetall was accepted as a reputable manufacturer of semiconductors. For example, it was recognised along with the well established giants such as Siemens and Telefunken by the West German Government agencies and sat on Government committees.

At the 1960 Hanover Fair Intermetall showed its extended range of silicon transistors with the addition of the OC463, OC466, OC468, OC469 and OC480 types.

|

Intermetall Silicon Transistors

|

||||||

|

t = 25oC, Common emitter, f = 1kHz |

OC463 |

OC466 |

OC468 |

OC469 |

OC480 |

Units |

|

Current amplification h21E |

20…30 |

20…30 |

≥40 |

- |

10…20 |

|

|

Static Current gain IC/IB |

|

|

|

≥10 |

|

|

|

Output Admittance h22E |

100 |

70 |

85 |

- |

25 |

μS |

|

Input Impedance h11E |

1.8 |

1.4 |

2.3 |

- |

1.1 |

kΩ |

|

Reaction Capacitance CB’C |

25 |

40 |

40 |

- |

40 |

pF |

|

Peak Collector Voltage |

10 |

10 |

10 |

32 |

125 |

V |

|

New Intermetall Silicon Transistors |

|

|

OC463 |

Rf transistor with a cutoff frequency of 5MHz |

|

OC466 |

Low noise small signal transistor |

|

OC468 |

Transistor with a high current gain |

|

OC469 |

Switching transistor with 0.35V saturation voltage |

|

OC480 |

Transistor for high voltages up to 125V |

|

Source Funkschau 1960 8 |

|

Intermetall also doubled the maximum power dissipation of its Zener diodes and silicon junction diodes.

In 1961 Intermetall added two varicap diodes BA110 and BA111 and three Germanium switching transistors, ASY12- ASY14.

With a focus on switching and power transistors for commercial use, Intermetall added a special power supply silicon rectifier diode BY102 for 220V mains rectification for the use in TV sets and for commercial applications, the BYY19 power rectifier diode. [Limann 1961]

Intermetall had now adopted the new European system for semiconductors:

|

First Letter |

|

|

|

|

A |

Germanium |

B |

Silicon |

|

|

|

|

|

|

Second Letter |

|

|

|

|

A |

Diode |

L |

RF type power transistor |

|

C |

AF low power type transistor |

S |

Switching type transistor |

|

D |

AF power transistor |

U |

Power switching type transistor |

|

F |

RF type low power transistor |

Y |

Power diode

|

Probably as a consequence of Shockley Semiconductor being part of the Group, from 1961 Intermetall had PNPN silicon four-layer diodes as part of its range.

Intermetall, being the only established German manufacturer which produced semiconductors exclusively, had the broadest range of semiconductors compared to Siemens, Valvo, Telefunken and SEL/SAF.

Alloy Diffused Transistor

In 1962 Intermetall released its first alloy diffused transistors following the technology developed by Philips and Mullard from 1957 onwards. These transistors were also known as “pushed-out-base” transistors.

Intermetall AF129 from Funkschau 1962 15

The Intermetall AF130-133 transistors were intended for use in FM receivers in the front end and IF stages. The AF129 could operate at up to 200MHz and was described as a "Pillen-Mesa” Transistor although there was little difference from other alloy diffused transistor types. [Funkschau 1962 7 andFunkschau 1962 15]

Both Siemens and Valvo offered similar transistors and much earlier than Intermetall. And at the high frequency end they led by a significant margin: The Siemens AFY10-AFY12 germanium mesa transistors could operate up to 600-1000MHz respectively [Funk Technik 1961 (1)] and the Valvo AF102 germanium pushed-out-base transistor up to 260MHz [Funk Technik 1961 (2)] according to their advertising.