4608A Ch= 458-3

Air King Products Co.; Brooklyn (NY)

- Country

- United States of America (USA)

- Manufacturer / Brand

- Air King Products Co.; Brooklyn (NY)

- Year

- 1949 ??

- Category

- Broadcast Receiver - or past WW2 Tuner

- Radiomuseum.org ID

- 31653

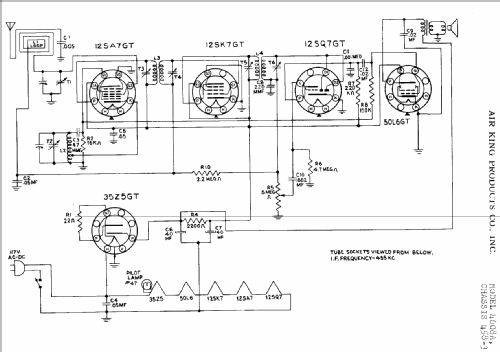

Click on the schematic thumbnail to request the schematic as a free document.

- Number of Tubes

- 5

- Main principle

- Superheterodyne (common); ZF/IF 455 kHz

- Tuned circuits

- 6 AM circuit(s)

- Wave bands

- Broadcast only (MW).

- Power type and voltage

- AC/DC-set / 117 Volt

- Loudspeaker

- Permanent Magnet Dynamic (PDyn) Loudspeaker (moving coil)

- from Radiomuseum.org

- Model: 4608A Ch= 458-3 - Air King Products Co.;

- Notes

- Built in loop antenna.

- External source of data

- Ernst Erb

- Circuit diagram reference

- Rider's Perpetual, Volume 19 = 1949 and before

- Other Models

-

Here you find 293 models, 147 with images and 240 with schematics for wireless sets etc. In French: TSF for Télégraphie sans fil.

All listed radios etc. from Air King Products Co.; Brooklyn (NY)

Collections

The model 4608A is part of the collections of the following members.

Forum contributions about this model: Air King Products Co: 4608A Ch= 458-3

Threads: 1 | Posts: 3

Fellow Radiophiles,

I bought this very cute Air-King 4608a Plaskon cased radio from Radio Age editor Ed Lyon at Radio Activity, which is the annual meeting of the Mid Atlantic Antique Radio Club.

This unrestored AA5 set is not valuable and needed a fair amount of clean up and speaker repair.

Electrical repair

I added a 0.25A slow blow fuse for safety, and replaced leaky capacitors with very small modern equivalents, while leaving the original caps in place with a shunt gray wire.

The electrolytics were bad too, and were not original. I kept the electrolytic cap red green and black wires, and insulated the new pair of 50uF 160V electrolytics with red heat shring plastic. This makes the new caps look somewhat like the originals.

This set uses an anusual method of grid bias for the 50L6 output tube. The 50L6 cathode is grounded, and it's grid is tied with a 150k resistor to the local oscillator control grid, which is pin 5 of the 12SA7 pentagrid converter. This method of bias has the advantage of eliminating the need for an electrolytic bypass cap at the 50L6 cathode to bypass the usual 180Ω kathode bias resistor. Leaving this resistor unbypassed, as is often done, cuts the gain of the 50L6 stage in about half, while reducing it's distortion somewhat. Grounding the cathode in this set makes it possible to get full gain from the 50L6.

I measured the grid bias level at the 50L6 as -4.5V, and the screen B+ voltage was 68V. Both of these voltages were a bit low. Some of the weakness was due to the 2.2k screen B+ resistor having drifted up to 2.6k. I decided to bring the screen B+ voltage to a more common value of 89V by paralleling a 2k resistor with the original 2.2k. The increased Screen B+ resulted in a more robust Local Oscillator operation, which generated -6V of grid bias for the 50L6. The increaced Screen B+ also improved sensitivity noticeably.

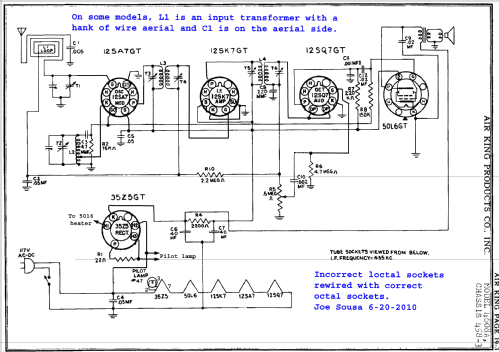

This version of the radio came with a set of OCTAL tubes which is correctly accounted for in the Rider schematic. However, the Rider schematic left the LOCTAL sockets in place. The following schematic was rewired with the correctly pinned out OCTAL sockets.

Keep in mind that the chassis of this radio is wired to the power line via the power switch, so the chassis may be hot when the radio is ON. I helped remedy this problem with a polarized plug and by adding a plastic film over the exposed portion of the chassis. The radio came with a replacement cord, that was not original.

Keep in mind that the chassis of this radio is wired to the power line via the power switch, so the chassis may be hot when the radio is ON. I helped remedy this problem with a polarized plug and by adding a plastic film over the exposed portion of the chassis. The radio came with a replacement cord, that was not original.

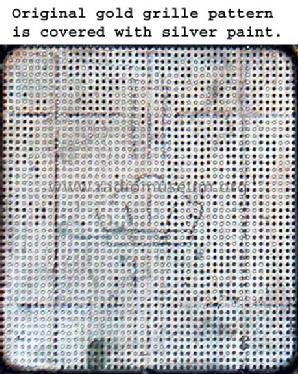

Case cleanup

The aluminum speaker grille was originally painted with gold paint and had a decorative line pattern and a crown. Someone along the way had painted the the grille with silver paint, which left most of the grille holes clogged and further obscured a deteriorated decorative pattern. I decided to strip the grille of all paint, and perhaps, at a future date, apply the original pattern, once I find out what it looked like, exactly.

The plastic dial cover was also very dull. I made it clear again with Novus fine scratch plastic polish.

The Plaskon case of this radio feels somewhat like Bakelite, and is impervious to every solvent I used to remove the grille and dial cover from the case. Some of these solvents included Acetone, isopropyl alcohol, lighter fluid and an aggressive label remover. The grille and dial cover had originally been glued in place with contact glue. I used this same type of elastic glue to put the grille and dial cover back.

Some signs of heat warpage are evident at the edge of the case, so I decided to protect these areas by gluing in some aluminum foil with contact glue. I also added a similar shield over the pilot light, and chose the shape of the shield to cast a nice shadow through the plastic.

The brass dial plate was finished in a dull gold, which had darkened over time. Washing this plate with Twinkle copper cleaning cream made the brass and the gold finish much brighter by gently disolving the oxidation. I am not sure if the gold finish was a kind of paint that was applied over the brass plate.

The most laborious part of the repair was the replacement of the badly warped 5 inch speaker cone. It seems that the original cone had been water damaged. After a quick search, I found no replacement 5 inch speaker cones.

First, I loosened the contact glue at the edges of the old speaker cone with acetone, then I used an X-acto knife to cut the cone near the voice coil, while taking care not to sever the voice coil wires. I saved the edge spacer.

After 4 tries, I was able to make a cone from "construction paper" that fit the speaker very well. "construction paper" is a kind of light weight card stock used in US primary schools for paper construction projects. I found a grade that seemed to have a porous texture and weight that was similar to the orignal cone.

The circular ridges of the "surround" were first drawn with a compass in pencil on alternate sides of the paper, then I used a ball point pen to score the pencil circles manually. Careful hand-bending of the scored circles produced the desired speaker "surround". I cut the last fold of the surround with about 16 radial cuts to let this last fold become coplanar with the speaker frame.

One of the trial cones shows a piece of removable tape that I used to train the paper into the cone shape by shaping it first into a tight cone, after the surround was formed.

There is no more than 0.1 inches of overlap at the radial cone seam.

I used contact glue to affix the surround edges to the speaker frame first. Then once this was set, I applied some contact glue over the cone-voice coil junction. This glueing sequence allowed for the original speaker spider to keep the voice coil aligned.

I glued a piece of soft felt as dust cover over the voice coil.

I measured the frequency at which the speaker gave it's greatest output with the old cone as 120Hz. This is the self resonant frequency, and I used a simple sinewave generator for this test. The new cone resonates at 140Hz, suggesting that my cone is slightly stiffer or lighter than the original.

This view of the speaker shows one scored ridge I drew on the back of the speaker to break up the speaker into areas of vibration, with the inner area for the higher tones. This probably did very little.

The sound quality is very good, even at loud levels, despite the slight physical imperfections of the cone.

A while back I managed a partial replacement of a similar speaker cone in a Teletone 990 AM radio.

Hopefully, this radio will never be so valuable or so rare, that a future owner will replace the speaker with a new one. Perhaps he/she will enjoy the new speaker cone in this radio as part of radio collecting history.

Regards,

-Joe

Joe Sousa, 20.Jun.10