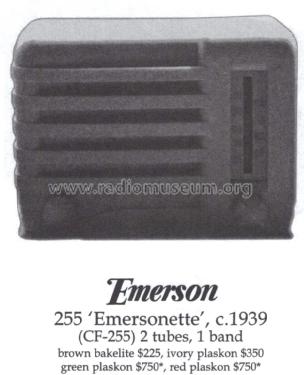

CF255 Ch= CF

Emerson Radio & Phonograph Corp.; New York, NY

- Country

- United States of America (USA)

- Manufacturer / Brand

- Emerson Radio & Phonograph Corp.; New York, NY

- Year

- 1939

- Category

- Broadcast Receiver - or past WW2 Tuner

- Radiomuseum.org ID

- 38862

-

- alternative name: Emerson Television

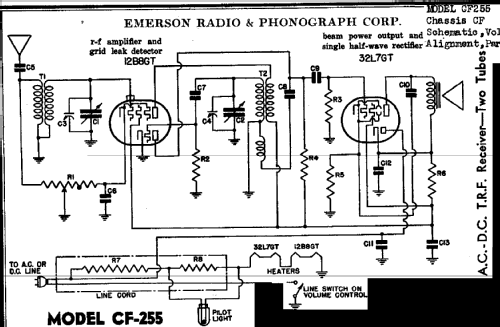

Click on the schematic thumbnail to request the schematic as a free document.

- Number of Tubes

- 2

- Main principle

- TRF without regeneration; 1 AF stage(s)

- Tuned circuits

- 2 AM circuit(s)

- Wave bands

- Broadcast only (MW).

- Power type and voltage

- AC/DC-set / 105-125 Volt

- Loudspeaker

- Magnetic loudspeaker (reed) generic. / Ø 4 inch = 10.2 cm

- Material

- Bakelite or Plastics (type unknown)

- from Radiomuseum.org

- Model: CF255 Ch= CF - Emerson Radio & Phonograph

- Shape

- Tablemodel without push buttons, Mantel/Midget/Compact up to 14

- Dimensions (WHD)

- 160 x 120 x 85 mm / 6.3 x 4.7 x 3.3 inch

- Notes

-

BC(540-1730kHz) band. Resistance line cord with pilot light section. Available in Ivory, Walnut, Green or Red cabinet.

- Price in first year of sale

- 6.95 $

- External source of data

- Ernst Erb

- Source of data

- Collector's Guide to Antique Radios (6th edition)

- Circuit diagram reference

- Rider's Perpetual, Volume 10 = 1939 and before

- Literature/Schematics (1)

- Table Top Radios Vol. 1 Stein 98

- Literature/Schematics (2)

- Radio Retailing (Radio & Television R.) (ad February 1939 page 4)

- Other Models

-

Here you find 2087 models, 1150 with images and 1645 with schematics for wireless sets etc. In French: TSF for Télégraphie sans fil.

All listed radios etc. from Emerson Radio & Phonograph Corp.; New York, NY

Collections

The model CF255 is part of the collections of the following members.

Forum contributions about this model: Emerson Radio &: CF255 Ch= CF

Threads: 1 | Posts: 3

I acquired this very cute Emersonette CF255 at the most recent Radio XLI swap meet in Westford Massachusetts USA. This set is actually "collectible", which has never been a reason for me to acquire a set. What caught my eye was the high impedance reed speaker nestled between two octal tubes - a rare combination.

I replaced the dryied out electrolytics, which were not original, anyway. I used two short cylindrical surface mount 33uF 300V caps and joined them inside orange heat shring tubing.

The 0.02uF audio coupling cap C9 from the Regenerative detector plate to the output pentode grid was leaky. Instead of replacing it, I shorted it with a piece of wire and added a small 0.02uF disc ceramic in series. This helped keep the original components in the set, while eliminating the harmfull leakage. This 0.02uF ceramicdisk cap is just visible at the center of the photo.

This set no longer had the original tapped 4 terminal resistance power cord. It came with a replacement 3 terminal resistance power cord with an open resistor. I hoped to reconnect the power cord resistor. I removed the cord from the set and compared the capacitance between the two power wires with the capacitance between either power wire and the resistance wire. If the two capacitances were similar, a break in the cord resistor near either end would be expected, but I got 150pF between the power wires and only 50pF between either power wire and the open resistor terminal. The break was somewhere in the middle of the cord, so I gave up on reconnecting the cord resistor.

My alternative to repairing the tapped cord resistor shown as R7 and R8 in the schematic, was to use a capacitor to drop the line voltage from 120VAC to the 44V @ 300mA required by the heaters. This approach has the advantage of not adding any heat dissipation under the chassis. I chose two 22uF 50V Y5V chip capacitors from TDK (C5750Y5V1H226Z). I bought these at www.mouser.com and their part number is 810-C5750Y5V1H226Z.

Y5V ceramic capacitors are marketed in a special way because of their special properties. They have full rated capacitance at 0VDC, but this capacitance drops to only 20% of the rated value at the rated voltage of 50V. The voltage rating has nothing to do breakdown voltage, it simply reflects the voltage at which the capacitance is at 20% of rated value. I have tested the breakdown voltage on these caps to be about 10x higher than the rated value, around 500V. The "high-k" (high dielectric constant) barium titanate that these capacitors are made of is somewhat piezo electric, so it's best to solder them to wires instead of directly to each other or on a board, when applying voltages well beyond the rated value. Note the 1/4" gap between the two capacitors. I also added a 220k resistor in parallel to discharge the caps when the radio is unplugged.

I put the missing pilot light back in the radio, but wired it in series with the entire power path, so that the 6.3V 400mA bulb also works as a fuse. The new cloth yellow wires go to the pilot light. The original design intended that the radio still work if the pilot light goes out and the pilot light was wired in parallel with a section of the line cord resistor. I have the opposite goal in mind, for safety sake.

Distortion from loose Speaker cone

Now the radio was fully functional, but there was significant distortion in the sound.

One cause of the distortion was that the small black brass cone that attaches the speaker reed with a pin to the paper cone was somewhat loosened. I applied a some acrylic clear nail polish to the brass cone and the rattle was greatly reduced. There is still a rattle at the loudest levels, and it is not caused by the vibration of the reed hitting the speaker armature.

Update: The rattle was not completely eliminated until I reflowed the solder holding the pin to the little brass cone at the center of the speaker. This was done with a pencil soldering iron from the front of the speaker, with just a little bit of solder.

Distortion from the 0.01uF grid leak capacitor

I have found over the years that if I can hear distortion, I can usually see it on the scope. Such was the case in the photo above where negative plate voltage spikes at the triode plate sounded pretty sour.

The cause of the spike distortion was the design value of C7=0.01uF for the grid leak detector. This choice can give the highest sensitivity, but at the expense of higher distortion with strong signals. The highest positive envelope peaks at the grid cause disproportionate increases in plate current. These plate current increases cause the negative voltage spikes seen in the photo above. The spikes disappear when the volume control R1 at the antenna is turned down to a level that is too soft for listening.

Turning down the volume at the antenna with R1 eliminates the distortion, but the sound becomes to soft for listening. It is also possible that the lower average modulation values used in 1939 had much fewer positive peaks than current modulation practice with sound compressors that greatly increase the number of positive peaks. I lower modulation index for the same sound level at the speaker, implies a higher carrier voltage at the grid leak which gets detected into a stronger negative self bias.

The photo on the right shows an experimental 0.01uF disc capacitor in series with the original C7=0.01uF.

There is another reason why the grid leak capacitor is used, and that is to allow for the DC bias point of the grid to be set independently by the grid leak resistor R2=10Meg. This resistor draws about 70nA from the 0.7V contact potential generated by the cathode space charge on the grid. The intention of the 70nA bias is to match the internal grid resistance to the impedance of the tuned RF LC circuit at resonance for best detection efficiency. The internal grid resistance should be between 100k and 1Meg with the 70nA DC bias.

The contact potential seen at the grid is also a function of plate voltage. Some detectors can take advantage of this by eliminating the grid-leak RC circuit entirely. The adjustment of the grid impedance is done by increasing the plate voltage until the contact potential is sufficiently lowered for a good impedance match between the LC tank circuit and the grid. For more details about grid conduction, check post #30 of Homebrew Radio.

Adding a 68pF grid-leak cap in series with C7=0.01uF lowered the grid leak time constant from 100ms to 0.68ms. The faster time constant can track the audio envelope such that the positive part of the envelope is flattened out, while pushing down the positive envelope excursions to the negative side of the envelope. For a further discussion on envelope tracking distortion check Diagonal distortion in FM limiters with special attention to post #2 by Prof. Dietmar Rudolph.

The 68pF is shown in the photo on the right connected at the coil end of the grid-leak circuit. This was convenient to experiment with, but the C7=0.01uf capacitor on the grid side of the grid-leak circuit is now floating at low frequencies, and picked up a noticeable increase in hum. The solution was to move the 68pF cap to the grid side of the grid leak circuit, so the original C7=0.01uF was grounded by the RF coil at audio frequencies. A slight re-tweak of the RF alignment was needed at the high end of the band after the 68pF cap was added.

The most comon choice for the grid leak time constant (R2*C7) is usually one that tracks the audio envelope, as became possible with C7=68pF. This gives the lowest possible distortion. One reason for the reduced distortion is that the audio content of the plate current is controlled by the negative side of the envelope, which sits at a lower distortion average negative bias.

Regards,

-Joe

Joe Sousa, 21.Feb.10