British ‘silica valves’

British ‘silica valves’

The technology of silica valves was developed at the Signal School, Portsmouth around the end of World War I. For power transmitting tubes silica was superior to glass in several aspects. It has softening point much higher compared with that of most glasses. Internal electrodes can operate at very high temperatures and silica walls transmit very well even in the IR spectrum, so to improve heat radiation from the plate while bulb remains considerably cool. For its properties silica bulbs could be made much smaller than glass ones, leaving few millimeters between their internal wall and anode. Silica exhibits considerably lower thermal expansion than glass, about one tenth, so reducing risks of cracks due to thermal stresses and shocks. Further it is mechanically stronger than glass and it has excellent insulating properties. For its properties silica was considered by the British Admiralty the best solution for the bulbs of high-power transmitting tubes, mainly for that operating at short waves.

Anode was made of tiny molybdenum ribbons, usually 2 mm by 0.1 mm, woven in a basket-like cylinder all around a cage made by molybdenum rods. Some longer rods were used to firmly anchor the anode to the silica envelope. Grids were made of molybdenum wire, spiral wound on ribs of the same material. Filament was made of tungsten wire, thoriated-tungsten being used only by the end of thirties for high-current pulsed applications. Silica anchor points were melted inside the envelope in the appropriate points to firmly hold electrodes in their right seating.

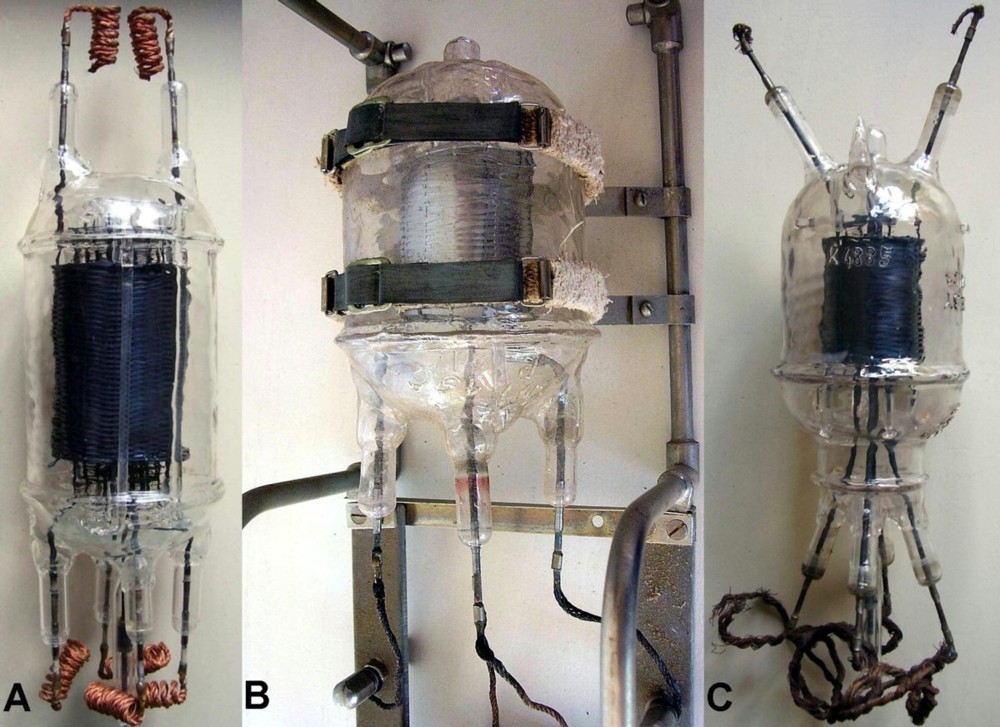

Fig.1 - Images of silica valves. A) NT63A tetrode, 2.5 kW plate power dissipation. One of the pillars, part of the internal silica frame which supports electrode assembly, is clearly visible in the middle. B) The NT45A was a small triode, 1.2 kW, here mounted in a plug-in frame. C) The NT57 was the first silica valve specifically designed for radar use in 1936. Here a sample of NT57D, same as NT57 but with graded glass sealing, instead of lead ones.

Soon after the war Captain Stanley R. Mullard, who had worked at the development of such tubes, founded the Mullard company, and started building silica valves. As shown in fig. 2B and C, their manufacture always remained a painstaking job and just the British Admiralty could afford their fearful cost. Silica valves no longer in working order had to be returned to equipped repair shops to be repaired. Here the reasons why these tubes are so rare: very few were made and not a single unit could be disposed when no more operating, rather all repaired and returned to service.

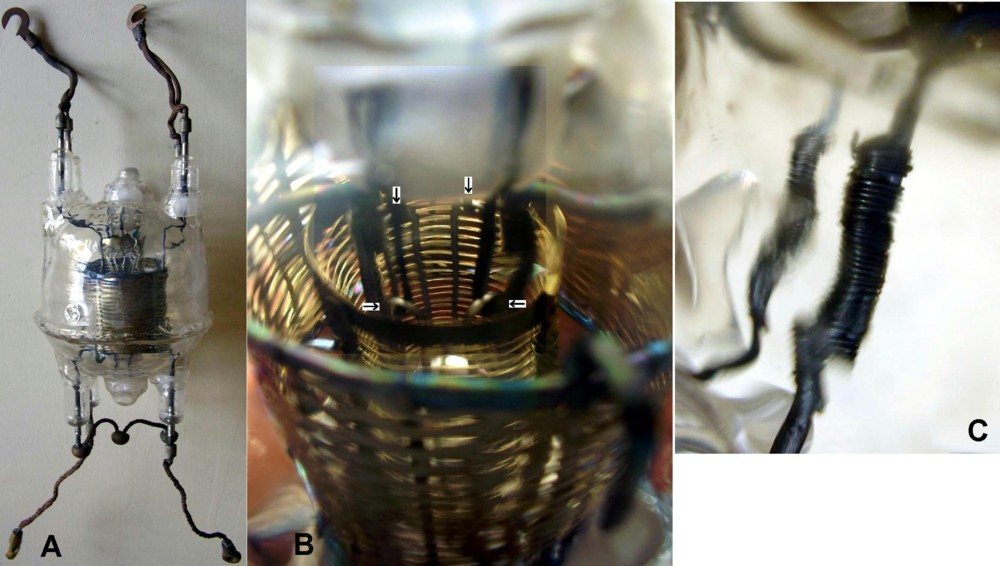

Fig. 2 - A) The NT57T with thoriated-tungsten filament was introduced in 1939. It required two fifth that of the NT57D and its emission was 50 percent greater. B) A close-up view of the interwoven molybdenum ribbons which formed the anode in a silica valve. C) Close-up view of the hand-made writings on the bulb, all made by molten silica fillet.

Due to their relatively small size and hence their capability to operate at rather high frequency, silica valves were also used very soon in radio-localization experiments. For this application higher frequencies and higher peak currents were required with respect to the existing transmitting tubes. The first silica valve specifically intended for radar pulse operation was the NT57. It was designed in 1936 by H.G. Hughes at the Signal School, Portsmouth. Here electrodes were quite short, about 8 cm, to operate at 45 MHz. The filamentary cathode was modified, using two thick hairpin-shaped tungsten wires. Requiring 15 V at 48 A, such a cathode was capable of about 5 Amps saturated emission.

Fig. 3 - A) The CV14 was designed to operate up to 240 MHz, but its operation proved to be unstable. B) Close-up view of its internal construction, with the basket-like plate of interlaced molybdenum ribbons, the grid of molybdenum wire and the hairpin-like filament segments, four of which evidenced by small arrows. C) Close-up view of wires jointed after the replacement of the grid inside a silica valve. The crude joint was made overlapping the two pieces of wire and wrapping them with tiny molybdenum wire.

NT57 was used in any kind of early warning radar sets, where high-power pulses were required. The most effective improvement was the introduction from 1939 of thoriated-tungsten filament which resulted in considerable increases of the emission and of the efficiency. But it was soon evident that the production of these tubes was by far too low for the wartime needs and silica tubes were replaced by other metal-glass types. CV14 is likely one of the last attempts to keep alive this outdated family. It had been devised for operation at about 240 MHz for small vessels and maybe even for use in CHL transmitters. Six hairpin-shaped filaments were used, for an estimated emission of about 50 A. Some samples were built but unfortunately their operation proved to be unstable and the design was abandoned.

After the war silica valves only survived in the CV313, a Mullard designed tetrode used as modulator for 2 MW magnetron in the Naval Type 992 TI set, and a few Mullard types proposed for industrial heating, as the TYS5-2000.

References:

- Callick, Metres to Microwaves

- F.M. Foley, Valve Developments for Naval Radar Applications, 1935-45

- All the photos from the ase-museoedelpro collection

To thank the Author because you find the post helpful or well done.