First Silicon Transistors

First Silicon Transistors

First Silicon Transistors

Copyright 2012 Mark P D Burgess

This article has been written to encourage members to contribute more examples of first silicon transistors by each manufacturer.

The story of the Texas Instruments first commercial silicon transistor has been widely told: For example as part of the corporate history of Texas Instruments [Pirtle 2005] and in The Early Semiconductor History of Texas Instruments [Burgess 2011]

But the development of the silicon transistor featured many technology breakthroughs that should be recognised in its history. There is much more to the story of the silicon breakthrough than the scientist most associated with it, Gordon Teal, allows. This article covers contemporary work by other companies and reframes the context of the work at Texas.

The announcement of the new transistor at the IRE National Conference in Dayton, Ohio on May 10th 1954 is probably best remembered for its theatre. Teal recalls:

“During the morning sessions, the Speakers had unwittingly set the stage for us. One after another they had remarked about how hopeless it was to expect the development of a silicon transistor in less than several years. They advised the industry to be satisfied with germanium transistors for the present. We of TI listened with great respect-and mounting exultation-because I had a handful of excellent silicon transistors in my pocket.”

Teal felt his paper had not done enough to capture the drama of the moment and decided to announce Texas Instruments was already in commercial production of the silicon transistor (really only 150 transistors in a pilot scale plant). Silicon transistor production was not years away and “contrary [to] the opinions expressed in this morning’s session this will begin immediately!”

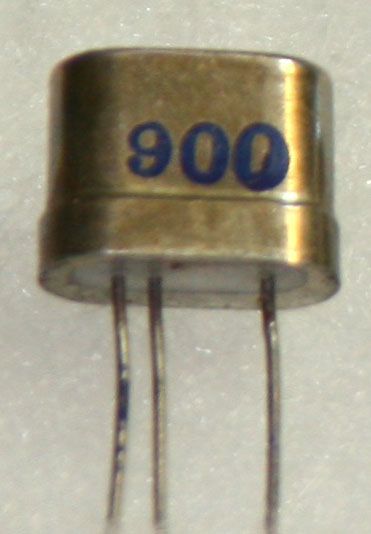

Teal then brought out a record player and demonstrated the performance of its all transistor amplifier which had one of its transistors mounted on a paddle. With a germanium transistor on the paddle he dipped it in oil at 150OC. The sound quickly died out. He then repeated the demonstration dipping one of the new silicon transistors in the hot oil: The sound was unaffected! (Picture Left: Early example of a 900 courtesy Joe Knight)

Teal then brought out a record player and demonstrated the performance of its all transistor amplifier which had one of its transistors mounted on a paddle. With a germanium transistor on the paddle he dipped it in oil at 150OC. The sound quickly died out. He then repeated the demonstration dipping one of the new silicon transistors in the hot oil: The sound was unaffected! (Picture Left: Early example of a 900 courtesy Joe Knight)

Those 150 silicon transistors secured the future of Texas Instruments and gave it a permanent place in the pioneering period of semiconductors. Teal quotes Fortune magazine for November 1961:

“The silicon transistor was a turning point in TI’s history, for with this advance it gained big head start over the competition in a critical electronic product; there was no effective competition in silicon transistors until 1958. TI’s sales rose almost vertically; the company was suddenly in the big leagues.” [Teal 1976]

![]()

Launch advertising in the June 1954 Electronics magazine of the Texas Instruments Type 900 Silicon Grown Junction Transistor (Courtesy Joe Knight)

Gordon Teal left a double legacy: he also championed the use of single crystal germanium while at Bell Laboratories and with Morgan Sparks made the first viable junction transistor there on the 10th April 1950, just four years earlier.

Silicon Transistor R&D at Other Companies

Silicon offered two important advantages: operation at higher temperatures and vastly lower reverse currents.

In 1954 all companies including Texas were pursuing germanium junction technology. But at least another five companies were also working on silicon transistors.

Two companies (1) made earlier announcements: Philco made a silicon surface barrier transistor which was reported in Electronics for February 1954 and a Raytheon silicon transistor was reported in Electronics for March of the same year.

The month following the Dayton announcement there was an entire session on silicon at the Semiconductor Research Conference of the IRE at Minneapolis: RCA described work on their SX-152 silicon alloy junction transistor; Raytheon their silicon grown junction transistors; Bell Laboratories presented three papers on silicon rate grown transistors, silicon alloy transistors and on wide area junctions by diffusion from the gas phase and Hughes Aircraft presented on alloy junction transistors. [Kurshan 1954]

But all of this was ignored by Gordon Teal asserting in his Oral History taken by Andrew Goldstein that only TI were working in silicon: “Most of them didn't know anything about silicon, except sand. Pure silicon—they didn't know beans about pure silicon.” And on why other companies might have neglected silicon Teal suggested that this was a case of unconscious incompetence: “most people did not know enough to have any brilliant thoughts about the subject. Why should you make something out of silicon when you already have germanium?” [Goldstein 1991]

While Texas was first with a commercial silicon transistor its grown junction technology did not survive more than a few years. Grown transistors were too expensive to make and silicon alloy transistors too difficult to make reliably to be long term survivors. The most far sighted company of all in the field was Bell Laboratories which recognized that only diffusion could meet future performance needs and single-handedly invented just about all the technologies needed for the production of high performance silicon transistors and integrated circuits. By 1955 Bell had produced the first silicon double diffused transistor. [Tanenbaum 2008]

Development of High Purity Silicon

High purity silicon was an essential component of any silicon transistor. Inadequate purity meant poor minority carrier lifetime in the base region resulting in low gain transistors.

Due to its high melting point (1410 C compared to germanium at 937 C), it was difficult to make pure silicon because at such elevated temperatures silicon was highly reactive (for example, it could react with its container or any traces of oxygen).

The semiconductor industry purchased high purity silicon from Du Pont but early on this required further purification. By about 1956 the practise in the industry was to buy in electronic grade silicon from Du Pont or Sylvania Electric Products. [Hunter 1956]

An anecdote from Ivan Getting, who led the Raytheon silicon transistor programme, attributed their success in beating Bell to the quality of the silicon his research team was using. “It seems that BTL had been receiving the purified silicon for well over a year. It was issued to the researchers in the order it was received. Thus the purified silicon that BTL was using was about a year old, whereas we received freshly refined silicon directly from BTL’s suppliers. Apparently, the purification process had been steadily improving and the older stuff contained traces of oxygen that substantially reduced electron mobility. In any case, the Raytheon Research Division was the first to produce operating high gain silicon junction transistors!” [Getting 1989]

Working at Bell Laboratories, Gordon Teal and Ernie Buehler had successfully made high purity and high quality single crystals of silicon and made grown silicon PN junctions. [Teal 1952] This followed the method pioneered in 1950 at Bell for Germanium in which a seed crystal was lowered into a melt and then withdrawn slowly, usually with rotation.

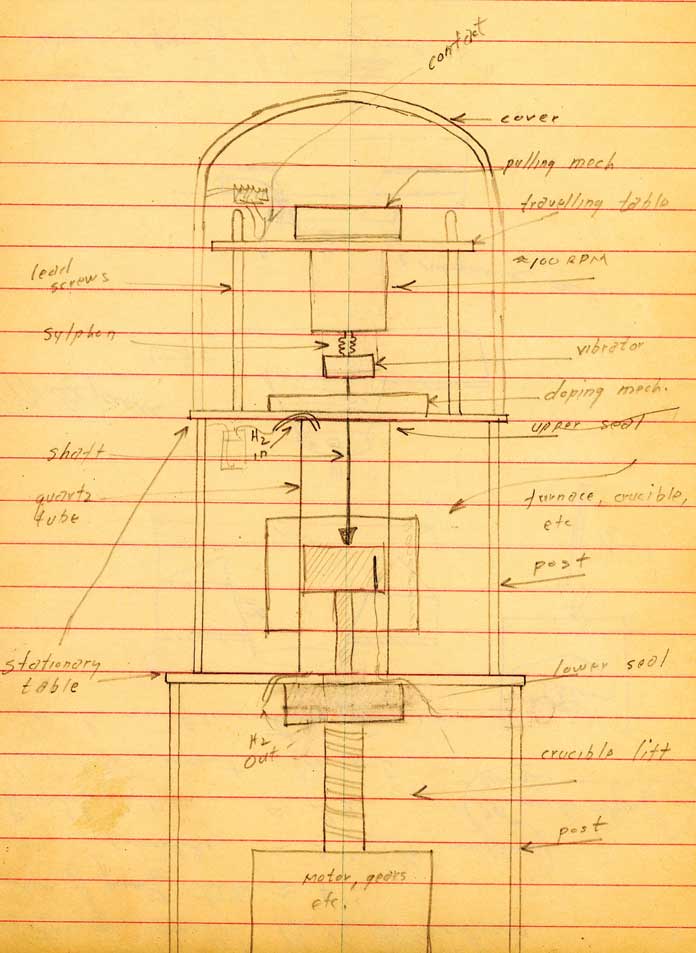

Texas Instruments learned this method during the April 1952 Symposium Bell ran for all the licensees and made a sketch of the crystal puller which they built. Single crystal germanium was made for the first time at Texas by June 1952.

Sketch of the Bell Crystal Puller by Boyd Cornelison of Texas Instruments. Scan courtesy of Ed Millis

When Philco announced their silicon surface barrier transistor (reported in the February 1954 edition of Electronics) they noted that these were laboratory prototypes and that a “major problem is developing a source of silicon pure enough for transistor work. The silicon used in transistors thus far made was by a costly and tedious re-purification process.”

Silicon Surface Barrier Transistor

Philco pioneered the surface barrier transistor in germanium and made a public announcement about a silicon version in January 1954. [Electronics 1954]

These transistors were made by directing two very thin streams of a zinc salt solution at opposite sides a thin slice of mono-crystalline silicon. The liquid carried an electric current that etched away the silicon. When the silicon was almost etched through, the current was then reversed in order to plate zinc on to the etched concave surface.

These transistors were made by directing two very thin streams of a zinc salt solution at opposite sides a thin slice of mono-crystalline silicon. The liquid carried an electric current that etched away the silicon. When the silicon was almost etched through, the current was then reversed in order to plate zinc on to the etched concave surface.

Transistors made had typical gains of 0.95 and up to 0.995 in the best case with a frequency response up to 10 MHz. “Dozens of experimental units have been produced and close uniformity of electrical characteristics noted.” The transistors were hermetically sealed. Picture adapted from Bradley 1953.

Silicon Alloy Junction Transistors

The alloy junction transistor was invented by John Saby of General Electric in 1951 and disclosed to the industry at the IRE Electron Devices closed conference at Durham in June 1951. This was also the forum that Bell used to describe their grown junction transistor.

The alloy junction process quickly became the industry standard for germanium transistors and was developed for silicon.

RCA

RCA developed an silicon alloy junction NPN transistor, the SX-152 from March 1954. [Knight 2008] This transistor was never commercialised. The work was presented by Herbert Nelson at the Semiconductor Research Conference of the IRE at Minneapolis in June 1954. [Kurshan 1954]

Raytheon

Raytheon also presented their work at the Minneapolis meeting and by the time they launched their silicon alloy transistors in 1956 there was a substantial body of published work, notably by RCA.

To make PNP transistors Raytheon assembled an N-type wafer, aluminium dots and the base tab in jigs designed to hold these components accurately in position while they were baked at temperatures between 800C and 1000C. Produced in this manner the aluminium dots resisted soldered connections due to an oxide layer on the aluminium. Late in the development program John Williams patented a method of soldering to aluminium dots using electrolytic etching of the oxide in a solder bath. [Williams 1957]

![]()

Raytheon CK790-793 Courtesy of Joe Knight.

Hughes Aircraft

At MinneapolisHughes Aircraft described their work: They had worked on NPN and PNP silicon alloy transistors using doped tin or doped gold alloys to create the collector and emitter. Some 80 alloys were tried in an effort to reduce the issues encountered with the silicon alloying process. They found that carrier lifetime in the silicon base region was radically reduced after alloying and that re-growth after alloying had to be promoted. Tin alloys were preferred because their softness reduced stress cracking but their low melting points reduced the potential operating temperatures. Gold alloys suffered stress cracking limiting lifetime of the transistor. Overall tin alloys were preferred.

Hughes pioneered an unusual axial design and used colour coding at the emitter end to identify the type number.

Hughes Aircraft HA7551(left) and HA7553 (right) Silicon PNP Transistors

Grown Junction Silicon Transistors

The first Texas Instruments transistor was a grown junction type.

The first of these was made in germanium by Gordon Teal and Morgan Sparks at Bell Laboratories by pulling single crystals from an N germanium melt creating the P layer by “pill dropping.” “Yesterday we pulled an N-P-N junction by doping twice (once with Ga-Ge second with Sb-Ge during a pull of a crystal. The unit was cut longitudinally…by etching away the N sides we were able to solder to the P-type bridge.” [Shockley 1976]

Raytheon and Bell had worked on silicon grown junctions transistors and the first of these to go public was Raytheon. Writing to the New York Times on 20th January 1954, Ivan Getting referred to the  problems of working with silicon noting “We here at Raytheon have had a large and very brilliant group working on these problems for a long time. I think we have substantially led the field in various steps to the point that during the last few months we have been making and testing silicon transistors. These have been tested at temperatures from 27 degrees C to 185 degrees C - the melting point of solder.”

problems of working with silicon noting “We here at Raytheon have had a large and very brilliant group working on these problems for a long time. I think we have substantially led the field in various steps to the point that during the last few months we have been making and testing silicon transistors. These have been tested at temperatures from 27 degrees C to 185 degrees C - the melting point of solder.”

In his biography Getting says that Raytheon first demonstrated a silicon transistor at the annual March IRE show in New York showing one operating in boiling water. This is confirmed in the edition of Electronics for March 1954 (including its picture, left) which reported that Raytheon had produced a grown junction NPN transistor with a base width of 1 mil and a gain of 40dB but that “Raytheon pointed out that quantity production was some time off. Silicon transistors are not expected even then to surplant germanium units.” [Picture left from Electronics 1954]

Morris Tanenbaum of Bell Laboratories produced a grown junction silicon transistor in January 1954. [Tanenbaum 1954]

He had commenced a programme on silicon transistors in 1953 using at first the crystal pulling and double doping technique Bell had used in its early germanium junction transistors. This failed because the quality of the silicon used gave insufficient minority carrier lifetime even across the thinnest base widths they could create (as little as one mil). So Bell tried the rate growing technique invented by Robert Hall of General Electric [Hall 1952] which gave even thinner base widths eventually enabling a viable transistor to be produced early in 1954. [Tanebaum 2008]

Early Diffusion Technology

Ultimately the winner was diffusion and Bell developed most of the technologies associated with modern semiconductors. This story is told in detail in “Diffusion Technologies at Bell Laboratories” [Burgess 2010] and the “History of Semiconductor Engineering.” [Lojek 2007]

A timeline for the Bell development is as follows:

|

1951 |

Calvin Fuller suggested that p-n junctions could be formed through diffusion in 1951. |

|

1953 |

Diffused silicon photo-electric cell made by Chapin and Fuller |

|

1954 |

Diffused silicon diode |

|

1954 |

Deposition of aluminium onto silicon structures by Goldey and Holonyak |

|

1954 |

First diffused base germanium transistor by Lee |

|

1954-55 |

Ring-dot diffused transistors by Holonyak |

|

1955 |

First silicon NPN diffused transistor in March using simultaneous diffusion to form the base and emitter by Tanenbaum |

|

1955 |

Oxide masking by Frosch |

|

1957 |

Photo-resist coatings and etching systems by Andrus |

|

1960 |

Epitaxial structures by Theuerer, Kleimack, Loar and Christensen |

First Diffused Silicon Transistors

Bell made its developments in diffusion available to 72 companies that attended the third symposium that it ran in January 1956. While at that time some 15 companies were making alloy silicon diodes most were satisfied that germanium devices could fulfil their needs for mainstream applications. Thus writing in the official history of Engineering and Science in the Bell System, Hornbeck notes that “the symposium aroused little enthusiasm among the licensees to undertake the major change in technology represented by diffusion.” [Smits 1985]

Despite Bell’s leadership, TI was first to market with a diffused silicon transistor: the 2N389. Its development was led by Elmer Wolff collaborating with Robert Anderson and Boyd Cornelison. Wolff followed the method developed by Fuller and Tanenbaum of Bell.

Wolff’s work was presented by him at the August 1957 Western Electronic Show and Convention held that year in San Francisco in a paper entitled “Diffused Fifty-Watt Silicon Power Transistors” [Wolff 1957]

Wolff’s transistors were made by taking wafers of N-type silicon, dicing them and using simultaneous diffusion to produce an additional diffused NP layer on all sides of each dice. Then the die were etched on one side to remove the NP layer creating the NPN sandwich.

An aluminum base ring was alloyed into the silicon die. This followed the Tanenbaum method of “simply melting the aluminum wire directly through the heavily doped N-type layer that covered it.” The wire did not short the emitter-base junction because as the wire solidified, it created an isolating p-n junction with the emitter surface layer. [Tanenbaum 2008]

2N389 transistor courtesy Joe Knight

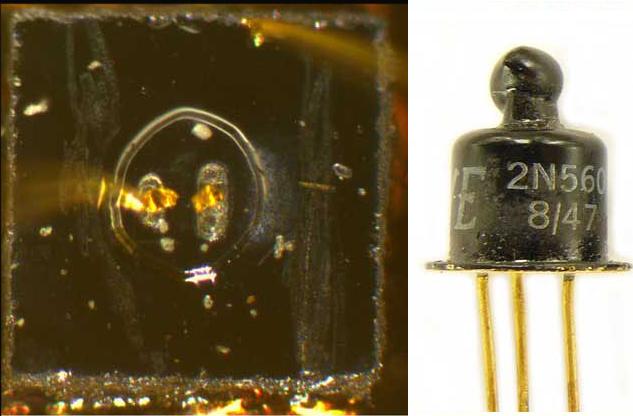

The first commercial Bell diffused silicon transistor was the 2N560 announced in 1958. An early version of this transistor with a crudely formed mesa structure is shown with its can type in the following composite:

Bell Laboratories 2N560 Silicon Diffused Transistor (1958)

Commercial Silicon Transistors

This survey shows the release date of commercial silicon transistors according to their journal advertising or other sources. Journal advertising can be taken as an indication that pilot quantities were available to their customers for developmental purposes rather than production quantities. Product data sheets may pre-date even pilot quantities.

First Commercial Silicon Transistors 1954-59

|

||||

|

Manufacturer |

Type |

Technology |

Date |

Reference

|

|

Dates relate to the first transistor in a series |

||||

|

Texas Instruments |

Grown Junction |

6/54 |

Electronics June 1954 |

|

|

The Texas Instruments 900 Series filled out over 1954-55 all based on the original grown junction development. |

||||

|

Germanium Products |

2N160-62A RD317A–322A |

Grown Junction |

12/55 |

Provisional Data Sheet JEDEC 1581 |

|

Raytheon |

CK790-793 |

Alloy Junction |

1956 |

Product Data Sheet |

|

Clevite |

2N260-62A |

Alloy Junction |

8/56 |

Provisional Data Sheet JEDEC 1739 |

|

Raytheon |

2N327-330 |

Alloy Junction |

3/57 |

Product Data Sheet JEDEC 1960 |

|

Texas Instruments |

Diffused mesa |

7/57 |

Knight 2007 Provisional Data Sheet JEDEC 2277 |

|

|

Hughes Aircraft |

HA7551/3 |

|

12/57 |

Data sheet |

|

General Electric |

2N451-4 |

Diffused |

1958 |

Knight 2007 |

|

Texas Instruments |

Diffused Alloy |

1958 |

Knight 2007 |

|

|

Western Electric |

Mesa Diffused |

8/58 |

Burgess 2010 JEDEC 2496 5/59 |

|

|

Fairchild |

2N696/7 |

Mesa Diffused |

8/1958 |

Lojek 2007 Provisional Data Sheet 8/58 JEDEC 2591 |

|

Transitron |

ST400 (second source 2N389?) |

Diffused |

3/1958 |

Knight 2007 |

|

Philco |

2N354 (T1159 became 2N495 or T1275) |

Surface Barrier |

10/1958 |

Ward 2009 Data sheet JEDEC 2032 5/57 |

|

Western Electric |

Diffused |

1959 |

Burgess 2010 |

|

|

Sylvania |

SYL-2505/2N1958 |

Epitaxial |

1961 |

JEDEC 3234 |

Footnotes

(1) This comment refers to junction transistors. See W J Pietenpol and R S Ohl, Characteristics of Silicon Transistors, Conference on Electron Devices, U. Michigan, Ann Arbor, June 22, 1950 referring to a silicon point-contact transistor.

Further Reading

For detailed accounts of the development of semiconductors by Texas Instruments, Raytheon, General Electric and Bell see Transistor History.

References

Bradley W 1953 Part I Principles of the Surface-Barrier Transistor Proc IRE 41 1702-6

Electronics 1954 Silicon Transistor Announced Electronics 27 February p6

Electronics 1954 Grown Silicon Transistors Appear Electronics 27, March p8

Getting I 1989 All in a Lifetime: Science in the Defense of Democracy Vantage Press New York

Goldstein A 1991 Gordon K. Teal, Electrical Engineer, an oral history conducted in 1991 by Andrew Goldstein, IEEE History Center, Rutgers University, New Brunswick, NJ, USA.

Hall R 1952 P-N Junctions Produced by Growth Rate Variation Phys Rev 88 139

Hunter L 1956 Handbook of Semiconductor Electronics 1ed McGraw-Hill New York

Knight 2007 A survey of Early Power Transistors: Texas Instruments

Knight J 2008 The First RCA Experimental, Developmental and Production Transistors Tube Collector 10 No 4 7-11 reproduced on the web at RCA Developmental Transistors

Kurshan J et al 1954 Report on the Conference of Semiconductor Devices Research Minneapolis MN June 28-30 1954 RCA Technical Report PEM-452

Lojek B 2007 History of Semiconductor Engineering Springer

Pirtle C 2005 Engineering the World: Stories from the First 75 Years of Texas Instruments 65-70 Texas Instruments Incorporated 1ed 2005

Shockely W 1976 The Path to the Conception of the Junction Transistor IEEE Trans on Electron Devices ED-23 July 597-620

Smits F 1985 A History of Engineering and Science in the Bell System: Electronics Technology 1925-1975 A T & T Bell Laboratories

Tanebaum M 2008 First-Hand: Beginning of the Silicon Age IEEE Global History Network August 2008

Tanenbaum, Morris 1954 Bell Labs Notebook No. 25505, page 30 (January 26, 1954) cited by the Computer History Museum in “1954 - Silicon Transistors Offer Superior Operating Characteristics”

Teal G Buehler E 1952 Growth of Silicon Single Crystals and of Single-Crystal Silicon P-N Junctions Phys Rev 87 190

Teal G 1976 Single Crystals of Germanium and Silicon-Basic to the Transistor and Integrated Circuit IEEE Trans Electron Devices ED-28 7 621- 39

Texas Instruments 1954 Press release May 10th 1954 New transistor will shrink electronic "brains"

Texas Instruments 1980 Proc 25th Anniversary Observance of the Transistor Radio and Silicon Transistor, March 17th 1980

Williams J 1957 US Patent 2857321 Method of Soldering to Aluminium or Other Material having Surface Oxide filed 15th March 1957 patented October 21st 1958

Wolff E and Anderson R 1957 Diffused Fifty-Watt Silicon Power Transistors Proc IRE 1957 WESCON Record Part 3 40-7

To thank the Author because you find the post helpful or well done.

The first German silicon transistors

The first German silicon transistors

In late August/early September 1956 the company Intermetall announced

with advertisement in the German professional journals for the first time their silicon junction transistors [1,2].

Intermetall was thereby the first company to offer and produce silicon transistors in the Federal Republic of Germany [3].

Intermetall was a subsidiary of the U.S. Clevite Corporation since 1955. Clevite made considerable effort to set up a modern semiconductor production for junction transistors. There was a significant transfer of knowledge from Transistor Products, an U.S: subsidiary of Clevite Corporation, to Intermetall [5].

In the U.S., Transistor Products had filed a series of silicon transistors in August 56 at JETEC:

2N260, 2N260A, 2N261, 2N262, 2N262A

Intermetall now offered a transistor series with identical data, but with usual German designation:

OC43, OC44, OC45, OC46, OC47

Production of these transistors was carried out, according to the general view, by Intermetall in Dusseldorf. These transistors were alloyed junction transistors of the pnp type

The maximum allowable collector power dissipation was specified with 200mW at 25°C, the maximum allowable collector voltage was up to 75V (OC45/2N261). (data from [4])

To avoid the same designation with the Philips/Mullard/Valvo transistors OC45 and OC44 - these transistors appeared at the same time or a little later - Intermetall renamed their OC series to

OC430, OC440, OC450, OC460, OC470

The maximum allowable power dissipation was now given with 220mW at 25°C [4]

The "Arlt Bauteile Katalog 1957" (with editorial deadline Novenber 1956)

lists both series OC43... and OC430 ... (with different prices) [6]

In 1958 an additional series OC430T with modified housing and attachable cooling clamp was released [7] :

OC430T, OC440T, OC450T, OC460T, OC470T

As a result the maximum power dissipation was further increased [4]

[1] Funktechnik 15/1956 p. 658

[2] Funkschau 16/1956 p. 454

[3] Richter, Transistor-Praxis 1.Aufl. 1956 p. 81

[4] Mende, Kristalldioden- und Transistoren-Taschen-Tabelle, 4.Aufl. 1963

[5] Handel, Anfänge der Halbleiterforschung und -entwicklung RWTH Aachen 2008 p. 202

[6] Walter Arlt Bauteile-Katalog 1957 p. 442

[7] Funktechnik 15/1958 p. 546

Intermetall advertisement Funkschau 16/1956 p. 454

To thank the Author because you find the post helpful or well done.