Pre WWII miniature tubes

? Pre WWII miniature tubes

I somehow got the idea that all miniature tubes prior to WWII were made by RCA. I know a lot of manufacturers made portable radios before the war that used miniature tubes. They may or may not have rebranded RCA tubes. I would like to confirm that they all purchased their tubes from RCA no matter how they are marked.

To thank the Author because you find the post helpful or well done.

Which date of WWII?

For some WWII started 1938. There were no B7G tubes then I think. For UK & Poland WWII started in September 1939. I don't think the designs registered by RCA till maybe November 1939, with models made in maybe late 1940 and certainly early 1941 (Before the USA entry to WWII). The RCA BP10 appears to have been first set to use B7G tubes. It's listed as 1940/1941. Pearl Harbour was 7th December 1941 so by then there were a lot of models from different Makers using B7G tubes.

But there are miniature tubes before the B7G series. I don't know what radio sets used them. Such as "Acorn valves". Also similar performance tubes (valves) with 1.5V 50mA direct filament except for output type of 100mA with octal base existed before 1T4, 1S4, 1S5, 1R5 line up. I don't know what date RCA started licensing other makers, but if it was before 1941 it can only be a short while. I don't believe any B7G tube existed prior to October 1939 outside a lab. The UK made "Covert" sets (Polish and Norwegian designed for dropping in German occupied territory as all radio sets confiscated) in 1943 seem to be using only RCA B7G tubes.

To thank the Author because you find the post helpful or well done.

picture

I remember a paper saying that Western Electric developed the "Miniature" tube, and the first product was 6AK5 or an equvalent. And that W.E. encouraged other tube makers to use it freely. However I can not find that paper at this moment.

There is an interesting picture in this paper :

(Other Bell System Technical Journal articles, 1922-1983)

To thank the Author because you find the post helpful or well done.

Western Electric Repeater tubes

The paper linked (Electron Tubes for a Coaxial System - 1951) is well worth reading for anyone interested in post WWII development of broadband amplifiers for coaxial cable (repeater tubes),

Lovely drawings of how the grid wires get smaller and closer to the Cathode.

Click_for full size Fig. 5 Click for full size. Fig. 12

They were able to get slightly better performance (2dB) using wire ends, but used pins and existing bases to allow easy field exchange and install of tubes.

W.E. probably developed the 6AK5 in 1942, but for the existing RCA base (which was developed in 1939 and commercially used in 1940). This RCA BP10 article discuses the RCA development of miniature tubes from 1939 to release many "personal" portable radio sets in 1940/1941. The 6AK5 though apparently developed as a repeater amplifier is better known in Europe as the 1952 and later EF95 IF/RF amplifier. The W.E. predecessor in the photo of the 6AK6 is the 386A which is wire ended is shown as 1939. There is also the W.E. 717A (possibly 1942 which is Octal base). It may have been omitted from the photo below as not significant in "repeater tube" development.

Click for full size Fig. 8

W.E. development of Repeater tubes

To thank the Author because you find the post helpful or well done.

7-pin miniature and all-glass tubes

Dear Paul, dear Michael,

Referring to the early question we should remember that, even if I ignore details about ownership of the shares, RCA was the daughter of Marconi and General Electric: see Tyne, chapter 16 about the founding of RCA. Many RCA branded tubes were built outside and General Electric was one of the preferred suppliers; at the same time many tube manufacturers started RCA licensed productions worldwide. For this reason we cannot exclude that GE made lots of the miniature all-glass tubes since their introduction. For the same reason, even with some delay, we cannot exclude that Marconi or other manufacturers started their own productions elsewhere.

The use of these miniature tubes by military, as in the BC-611, certainly required the presence of alternate US sources, even if the same GE could be the second source.

Going to the generic overview on all-glass tubes, their use increased through the ‘30s primarily for high frequency applications. The two common ways to raise operating frequencies of receiving vacuum tubes were the scaling down of electrode size, even with tighter spacing, and the reduction of parasitic parameters in the connections. RCA acorn tubes, as the 955 announced in March 1935, can be considered the early really high-frequency types to enter in production. Use of terms VHF or UHF could generate confusion, since in the ‘30s any frequency above some 40 MHz was considered to be UHF. Western Electric answer was a line of small tubes, either baseless and with octal base. The picture below shows a baseless 384A, an octal based 387A and the single-ended 717A, the most known derivative of the 384A. The 717A in 1943 gave origin to the 7-pin miniature 6AK5. Even the electrode assemblies of acorn tubes were later repackaged into 7-pin miniature envelopes, as the 955 that gave origin to the 9002.

But we are still talking of conventional concentric electrode structures. Planar structures were first tried to reduce interelectrode spacing, due to the tighter obtainable tolerances. Here is the scan of a very early RCA paper on planar tubes for wavelength down to 30 cm, reprinted from Proc. IRE, Dec. 1933.

Planar triodes also were ideally suited for use in stable grounded grid operation, with the grid connected to the metal shield insulating the input and the output resonators. Around 1939, the development of reliable glass to copper laminae seals originated disc-seal triodes, with planar grid disc, capable of operation in the UHF and even in the SHF region.

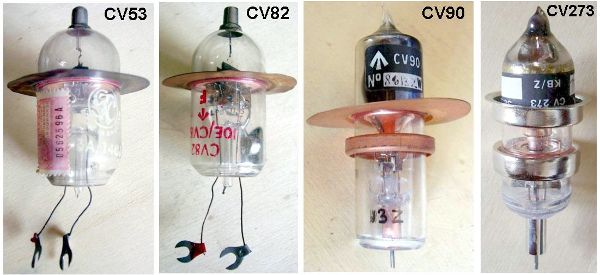

The early family of British disc-seal triodes was developed at STC Ilminster by the receiver group, since the design of planar tubes went up parallel to the design of RF grounded grid amplifiers. The first low-noise amplifier triode was the S25A or CV16, soon followed by CV53 and by CV88, all using the same grid-cathode assemblies.

Another disc-seal triode from STC was the CV82, intended for use as oscillator and available since early 1941. Later in 1943 GEC introduced the CV90, with the glass base folded around the coaxial heater/cathode plug. This design was superseded in 1945 by the CV273, forerunner of the British family of ‘rocket’ tubes.

A line of Sylvania and Litton ‘rocket’ types was developed in US starting from the CV273 design. The line included amplifiers and oscillators capable of operation up to some 3 GHz. In the figure below some samples of this family.

General Electric followed a different design approach for its line of disc-seal triodes, developing the so called ‘lighthouse’ tubes. The first type was the GL-446, introduced in the early 1941.

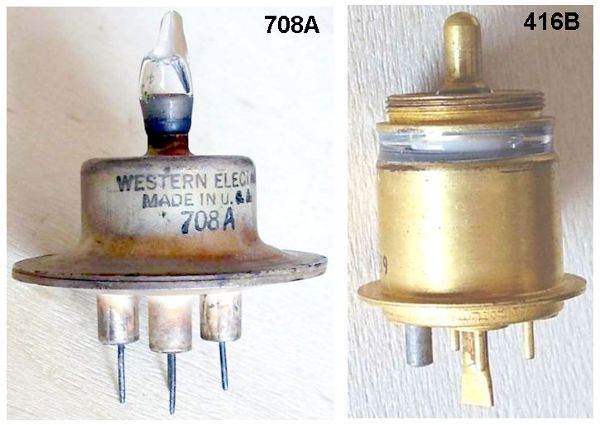

Strange enough, Western Electric was quite skeptic about planar tubes, preferring a conventional electrode structure mounted in a shielded and grounded body. The 708A, introduced in 1941, was superseded only later by the excellent 416A planar triode design and the same design was probably derived from GE prototypes handled as part of the cooperative war effort.

To thank the Author because you find the post helpful or well done.

> I remember a paper saying that

I remember badly.

This is the paper I was thinking of.

Development and Production of the New Miniature Battery Tubes - an article by N.R. Smith and A.H. Schooley the originally appeared in the RCA Review, April, 1940, and scanned from Electron Tubes, Vol. I by RCA. This explains the development of the first 7-pin miniature tubes: the 1R5,1T4, 1S4, and 1S5. 7 pages, 849 Kbyte pdf format.

Of older interest:

Recent Developments in Miniature Tubes - an article by B. Salzberg and D.G. Burnside that originally appeared in the Proceedings of the I.R.E., Oct. 1935, and scanned from Electron Tubes, Vol. I by RCA. This explains the development of the first acorn tubes: 954 and 955. 16 pages, 1.3 Mbyte pdf format.

To thank the Author because you find the post helpful or well done.

Sarnoff!

> even if I ignore details about ownership of the shares, RCA was the daughter of Marconi and General Electric

RCA's childhood is complicated.

After its founding, and especially after an anti-trust settlement, the story of RCA is all about David Sarnoff. He had vision similar to Steve Jobs (but different personality).

> Many RCA branded tubes were built outside and General Electric was one of the preferred suppliers

In anti-trust, GE was asked to stop radio-work for a time, then RCA would market GE products. RCA and GE were "good friends" for many years.

Cunningham and RadioTron come into RCA, bringing tube production tooling and distribution know-how.

Through the 1930s, Sarnoff went far beyond RCA's original mandate to unify radio patents, absorb the guilt of seizing Marconi's US assets, and re-organize monopoly positions in the electronics field. Sarnoff grew a massive research and development organization. RCA introduced the Octal, the all-metal tube, figured how to wind aligned-grid at commercial prices and combined that with critical Distance effects to evade the Power Pentode patent and produce 807/6L6, and then the Miniature tube.

As for where the tubes were made.... on one hand, most of the progressive commercial tube making faclities were controlled by either RCA or GE, and they were good friends. If one company were better equiped for a specific tube, it was made there. If a tube had huge demand it might be made in two factories, perhaps under different "ownership" if that worked best. If buyers wanted to see a certain brand on a tube, tubes were branded according to the contract. If a large buyer really needed alternate sources to ensure steady supply, the tube type was tooled-up at two faciities.

> idea that all miniature tubes prior to WWII were made by RCA.

It seems likely. Introduced 1939 for a narrow market. While many in the USA were anticipating war, it was not until 1942 that the US government began formally allocating production to war material, when car and radio production for civilian use ceased. (My brother has a 1941 Plymouth, there were a few 1942 Plymouths produced but nearly all went into government service.)

So pre-War (1939-1942) civilian production of miniatures would be small, not enough to justify a second production facility. Any other commercial users would be comfortable buying from RCA. During and after 1942 is "war" and outside the scope of your question.

To thank the Author because you find the post helpful or well done.

A little date adjustment

SCR-536 Radio Set, or its component BC-611, was designed in 1940 and was in production since July 1941, well before Pearl Harbor. So, if we refer to the war blast date for US, we must assume that a second source for miniature tubes was qualified and active before the war.

About the plant where tubes were made, just the people really involved in the productions have the answer. As far as I know, tube manufacturers usually bought lots of finished or semiprocessed tubes from outside, depending upon how much their production lines were overloaded. I saw Sylvania branded tubes 'Made in Germany' as example. But even in case of lots too small to be efficiently handled on their lines, they subcontracted productions outside.

To thank the Author because you find the post helpful or well done.