Fifty-two (52) Ch= 5C2

Crosley Radio Corp.; Cincinnati (OH)

- Country

- United States of America (USA)

- Manufacturer / Brand

- Crosley Radio Corp.; Cincinnati (OH)

- Year

- 1934

- Category

- Broadcast Receiver - or past WW2 Tuner

- Radiomuseum.org ID

- 240333

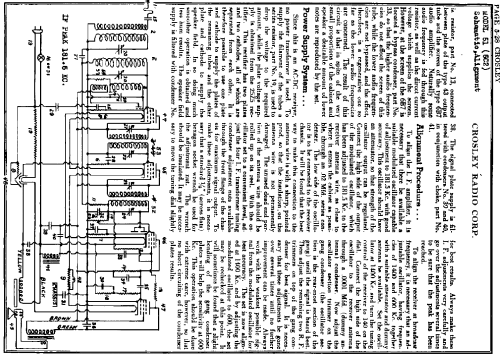

Click on the schematic thumbnail to request the schematic as a free document.

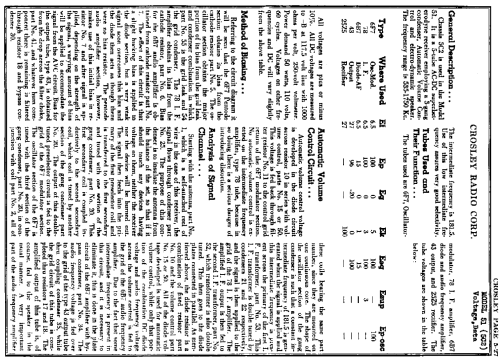

- Number of Tubes

- 5

- Main principle

- Superheterodyne (common); ZF/IF 182 kHz; 2 AF stage(s)

- Tuned circuits

- 6 AM circuit(s)

- Wave bands

- Broadcast only (MW).

- Power type and voltage

- AC/DC-set / 117 Volt

- Loudspeaker

- Electro Magnetic Dynamic LS (moving-coil with field excitation coil) / Ø 4 inch = 10.2 cm

- from Radiomuseum.org

- Model: Fifty-two Ch= 5C2 - Crosley Radio Corp.;

- Shape

- Tablemodel without push buttons, Mantel/Midget/Compact up to 14

- Dimensions (WHD)

- 11.5 x 8 x 6 inch / 292 x 203 x 152 mm

- Notes

-

Also known as model 51(?).

This model was prominent shown in the 1940 film "The Great Dictator" by Charlie Chaplin.

- External source of data

- Ernst Erb

- Source of data

- The Radio Collector's Directory and Price Guide 1921 - 1965

- Literature/Schematics (1)

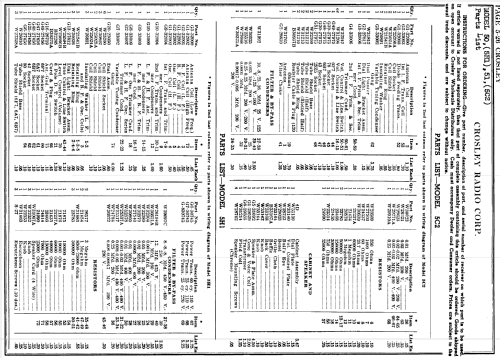

- Rider's Perpetual, Volume 1 = 1931/1934 (1919 to 1931) (for chassis 5C2)

- Author

- Model page created by Konrad Birkner † 12.08.2014. See "Data change" for further contributors.

- Other Models

-

Here you find 1813 models, 1053 with images and 1306 with schematics for wireless sets etc. In French: TSF for Télégraphie sans fil.

All listed radios etc. from Crosley Radio Corp.; Cincinnati (OH)

Collections

The model Fifty-two (52) is part of the collections of the following members.

Forum contributions about this model: Crosley Radio Corp.;: Fifty-two Ch= 5C2

Threads: 3 | Posts: 3

As I wrote in my previous article, when I found this radio at the flea-market, it was in very bad condition, with a lot of missing parts. Despite of that, I have purchased it for several reasons: it's very strange to find such an American vintage model here in Eastern Europe. Also, it seems to be a rare model, even at the RM only one member posted that model. Finally, its restoration would be a real challenge for me.

The first pisture shows the radio as it came.

Both knobs are missing as well as the volume control plate.

Next picture is a back appearance and the tubes I found inside. Back cover is missing, one tube was not original and two other were dead.

Next two pictures show both sides of chassis:

„Speaker horror“

Restoration and reconing the speaker was described in my previous article, but here I only want to remind you how it looked like!

Restoraton begins with cleaning. The chassis was cleaned using metal brush and anticorrosion fluid.

To clean the tube socket contacts I used an interdental brush and contact-cleaning fluid.

By sockets for first two tubes you can see fixation springs for tube shields, which also were missing. After some search I happily have found, at the eBay, the original type shields. There I also have found replacements for missing and burned-out tubes.

After cleanig the chassis, I had to check all parts. Some capacitors were leaking and resistors were broken or open, including the dropper, which was improvised sometimes in the past.

Next photo shows all parts to be replaced:

Variable capacitor was cleaned in ultrasonic bath.

As I do always, all paper smoothing and blocking capacitors had to be replaced with good electrolytics. To restuff its can, I had to open it, pull out the old capacitors and raplace them with modern electrolytics. All steps of doing that are shown in following pictures:

Now, the chassis is rewired with new parts and some connecting wires with crumbled isolation were changed.

And now came time for some cosmetics. First, the cabinet. It was so damaged that I had to give it to an proffesional furniture restorater. Here si how it looks after his work:

New speaker cloth is not even close to original, but when I find something better, it could be replaced.

Since the rectifier and output tubes generate much heat which can damage the cabinet finish, I put some protecton:

Now the radio was assembled and an new back cover was made.

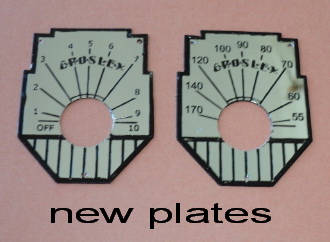

There were some problems at the front. When came, radio had only one front plate (tuning control). Second one, for volume control, was missing. Copying the size and shape of existing plate, I drew the plate for volume control and gave it to professional engraver to make it of nickel-plated brass, 0,5 mm thick. Here they are: at right is the old, original plate and left is the new one, for volume control:

If someone wants to make those plates, I can send the templates by mail.

Second problem was the tuning pointer which was missing too. Variable condenser has coaxial 3:1 reduction so that the knob has to be rotate 6 times to get the rotation of 180 degrees of the rotor. Very nice, but I had to make an adapter to fix the pointer at the outher shaft of the condenser. Inner shaft is for the knob. I made that adapter of brass using my lath. The pointer itself was made of transparent plastic with centered red line, fixed at the support (adapter) with three M2 screws.

The original knobs were also missing, so I put what I had, hoping that one day some close to original will be found.

Finally, restored Crosley looks like this:

For alignment I performed standard procedure, using modulated signal of 182 kHz for IF, and oscilloscope. Fortunatelly, the coils were OK and only the IF and trimmer capacirors had to be adjusted.

To ilustrate how it works, I posted an audio clip to its model page. That is BCB-scan, with some interferences from local switching chargers in the neighbourhood. No MW AM stations are active in my country, as in most of Europe, so that only some Hungarian and Romanian stations could be heared with this receiver.

I hope that this presentation can help , and for any details feel free to ask me.

Best regards and enjoy our hobby!

Appended by Dietmar Rudolph

Dejan Momirow wrote on April 1th:

I noticed an error in my last article about the restoration of this radio! In part about variable condenser which has coaxial reduction 3:1 I wrote that you have to turn the knob 6 times to get the full scale rotation (180 deg) of its rotor. But, that is wrong! It should be a half of the reduction ratio, be 1,5 times!

Sorry!

Dejan Momirov, 31.Mar.21

Recently I've got a beautiful Crosley radio from 1934, model Fifty-two, Ch-5C2, but badly damaged. You can see it in my collection at RM. I began its restoration with reconing its electrodynamic speaker.This is an early type, model 214B, with field coil, hum-bucking coil and, of course, the voice coil.

The output transformer is mounted on speaker frame.

It was corroded, the cone was torn with missing parts, magnet gap full of dirt and some of leads broken .

To begin with, I had to disassemble the speaker. First I cut off what is left from old cone, desoldered the voice-cone leads, removed the central spider screw and removed remnants of the cone with attached voice-coil carefully, not to damage the coil. Using surgical blade Nr 11, I removed all peaces of the cone from the coil body and the spider, so that they were separated.

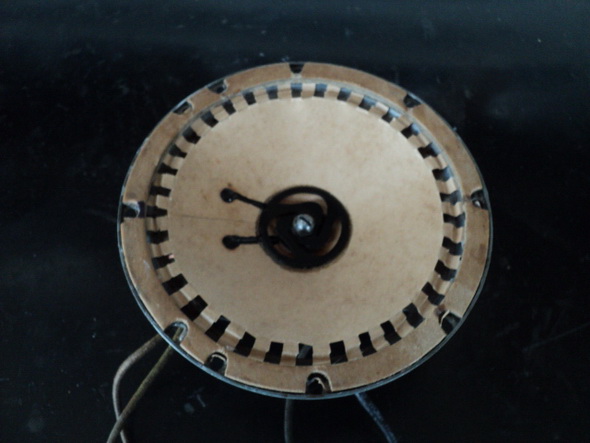

Windings of the voice-coil are temporary fixed with masking tape because they are wound to the very edge of the coil-form and were a bit loose. Later, I fixed them with thin layer of "crazy glue". This is important because all force which moves the coil and the cone is generated in the windings wire which therefore has to be firmly attached to the coil body. The spider itself was made of 0.6 mm thick pressed paper and its central hole is 5mm. As the screw is about 4 mm, it is possible to do some fine adjustments in centering after everything has been fixed. Fig. 5 shows the complete spider set.

The hardware is shown here.

I cleaned all parts and treated them with an anticorrosion fluid. The original back-side gray paint was preserved. All coils and output transformer were checked for open circuit and some leads had to be repaired.

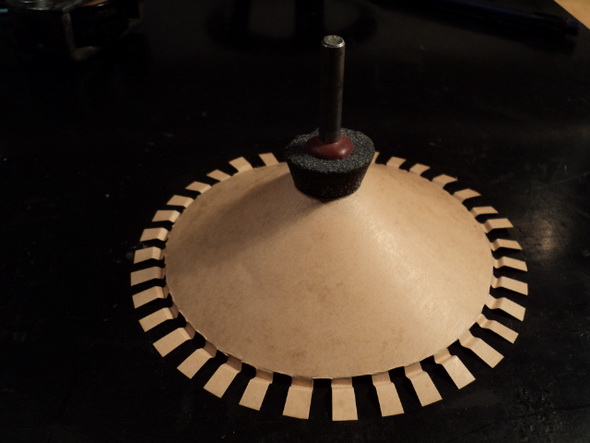

And now comes the most important part - the new cone. First, I found an suitable material - transformer insulating paper, 0.15 mm thick, and then performed all necessary measurements: diameter of the speaker basket (124 mm), front opening of the cone (D1=100 mm), central opening of the cone, where the voice coil has to be fixed (D2=19,7 mm). Actually, the outer diameter of the coil has to be measured. The angle of the cone has to be determined (alpha=27 deg., cos=0.891). To calculate the cone I have found great help in two articles: "Speaker Cone Math" by Mark Palmquist and "Replacing Early Paper Speaker Cones" by Larry Weide. So, I calculated and cut out the flattened cone.

The calculated values were: outer diameter: 124/cos alpha=136.2 mm, cone front opening diameter: D3=D1/cos alpha=112.2 mm, central cone opening diameter: D4=D2/cos alpha=22 mm and the angle of the pie-shaped cutout : beta=(360 - (360*D2/D4)) = 37.6 deg. Before cutting away this section, I left and marked a 6 mm glue-lap. From the edge of the flattened cone I made numerous cuts at 4-5 mm distance, to the marked cone diameter (112.2mm). After that was done, every second tab was cut off to make vibrating of the cone easier. Those spaces could be covered with some elastic material (of surgical gloves, for example), but this is not a Hi-Fi device and is not really necessary. Then, the paper was carefully bent and glued to the mark-line with a nitrocellulose-glue. To get a flexible fixation, I creased all the tabs.

Central opening was trimmed to the exact diameter of the voice-coil using a cone-shaped grinding stone.

It has to fit firm, at first without any glue!

Note here a paper inside the coil! It has to keep equal distance from the inner magnet pole at 0.15 mm. This photo

shows reassembling of the speaker. After putting field- and hum-bucking coil in place, the basket, the output transformer and the front magnet plate were fixed loose! First I had to adjust an equal distance between both magnet poles. By my speaker, the gap was 0.8 mm. The coil is 0.4 mm, so the clearance between coil and both magnet poles has to be 0.2 mm. When the distance of 0.8 mm was secured using some cardboard and paper, both screws were tightened firmly. Now the voice coil was fitted into the cone with both wire endings at front side, the cone was centered to the inner magnet pole with 0.15 mm thick paper strips, and cone was temporary fixed to the speaker basket.

Adjust the depth so that only 2 or 3 turns of the voice coil winding are visible above the magnet plate. Now the coil body has to be glued to the cone. This joint has to be the strongest one, so I used two-component epoxy resin.

After I let it to cure for 24 hours, I put two brass hollow rivets of 2 mm at about half a cone radius. Two peaces of 0.2 mm bare wire were hammered under the brass washers and rivets and soldered to the voice-coil wire ends.

On the back side I soldered two flexible leads, being braided desolder-wick 1mm thick, 5-6 cm long.

When all that was done, I put the cone back on the frame, centered the voice coil again,

checked the depth of the coil,

put some elastic glue (neoprene) on the frame rim , another layer of glue on the gasket and after a few minutes drying, pressed all that firm together. After cure, the rivets and their connecting wires are covered with black nail-polish. Then I removed the centering strips of paper, fixed the spider and glued it to the cone, also using the strong epoxy.

After cure, centering has to be checked! The coil must not touch the magnet poles! If it does, loosen the central spider-screw and slide the spider a bit aside until it doesn't and tighten the screw again. Then, the original repainted metal front plate was put back. Finally, I soldered all leads to the contact plate on the output transformer.

The hum-bucking coil is connected in series with the voice coil to the secondary of the transformer. Keep the original polarity of both coils- they must be in opposite phase to buck the hum! Now, the time has come to test the whole work. First, I checked the field coil using my lab's power supply.

It was OK : 90 V / 30 mA. To test the frequency response, I used the sine-signal from my signal-generator, amplified by a simple test-amplifier with ECL82, connected to the primary of the original output transformer.

The first test was at lower range 40-650 Hz. It was OK, and resonant frequency was about 140 Hz.

Second test was at higher range and the speaker responded nice from 650 up to 8000 Hz - more than enough for the BCB.

As the final test, I fed the audio signal from my Standard Transistor Radio to the amplifier and I was satisfied with the sound.

All that was a lot of work, but I find it worthwhile. If some of you has done something similar, I would appreciate any comment or advice.

Dejan Momirov, 01.May.14

Hi,

Does anybody know where I could find volume cintrol plate and original knobs for Crosley model 52 - 5C2, as well as back panel? Thanks

Dejan

Attachments

- Crosley model 52 (51) (143 KB)

Dejan Momirov, 17.Apr.14